Let’s Keep it Clean in Here

If a company gets labelled as ‘dirty’ or people get sick eating the food, that’s a label no brand can easily recover from

What’s Worse Than Downtime on the Production Line?

Few things are. It can be absolutely heartbreaking having downtime due to technical faults. Faults that may not even be able to solve swiftly. Or how about downtime when having to upgrade or replace technology, because they are no longer suited for the market demand or changes in the supply chain. Its just…

Well, there is one thing, that is even worse. So bad in fact that it often causes major downtime and technology replacements as a result. And that is… having to recall products due to bad hygiene.

Standards are high in the Food Production Industry, no doubt. But still, it happens every so often, that a company have to recall an entire batch. Most often due to ingredients gone bad in which case it may be outside the company to fix – it still shows Quality Control didn’t kick in and caught the problem in time before products was packed, stacked and shipped.

But sometimes hygiene control is the cause of the problem. In those cases, it is usually because the production line has many manual operations in the process. Humans. Having people in near contact with the product is a risk hygiene-wise. And hygiene has been the center of attention for years now.

If a company gets labelled as ‘dirty’ or people get sick eating the food, that’s a label no brand can easily recover from. People remember that, talk about it and share their experiences. Bad hygiene in the production line must be one of the worst things that can happen to a production plant – if not the worst.

Still, many companies have been running for years without any problems at all having people working in the packaging zone. If it isn’t broken, why fix it?

For one thing, even if the production line works well and the highest of standards are upheld, the risk itself is still there. It only takes a moment of forgetfulness before the line must undergo an entire cleaning operation.

Another thing is the scalability. New demands keep arising which brings change and flexibility into the mix. The line may have been running for years, but how about the years to come – will it still look the same? A lot more food needs to be produced in the future to support the world population. Climate changes can stretch the supply chain and push prizes upwards. Being able to adapt is a parameter in the competition to come.

Also read: The world may be changing faster than your production line

When people have to adapt and change it will increase the risk of errors happening. It may even become stressful. Too stressful and they look for other opportunities. It can be more difficult to position these roles, as the production labor-force is not growing as fast as the demand.

Having people in the production line – especially in areas where they can easily be removed from the equation – will always be a risk. On many levels: hygiene, competitiveness and scalability.

Automating the processes that are easy to do with off-the-shelve technology… get it done!

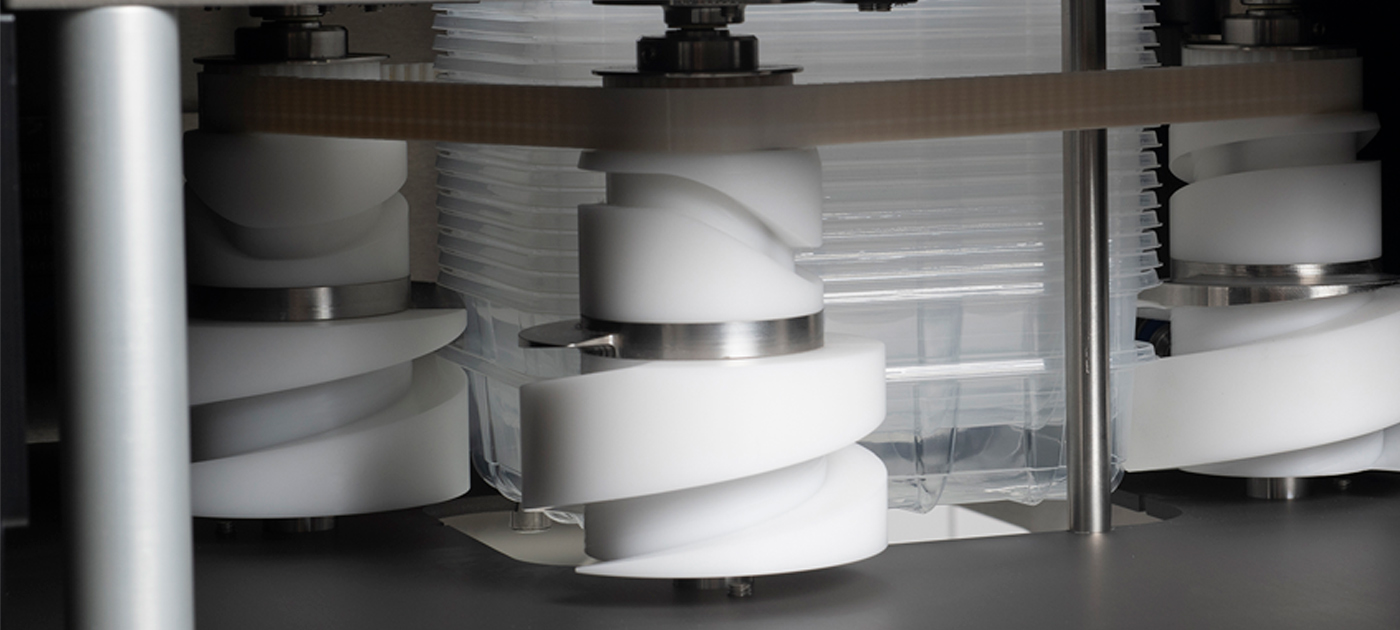

Doing it doesn’t mean you will become risk-free – no business is that. But with QUPAQs denesting and handling solutions for the entire End-of-Line, you will have minimized it significantly. All while ensuring you can scale production and adapt to many different scenarios. That could be new tray types, sizes and materials.

QUPAQs denesting and loading machines are incredibly easy to clean and done in no time. Switching tools can be done in a matter of minutes. You can get both Servo-driven (electric) solutions – INTRAY – and pneumatic-driven (compressed air) solutions with ANYTRAY

In any case you should always look on how production can be strengthened with the Quality Assurance needed and as minimal risk as possible. The possibilities are many and ever evolving so be sure to get the right partnerships with a proven record of reliability, flexibility and the return on investment you will expect.

Some products can seem too complex to automatically put in trays. But technology have come far in this field. Today its possible to do faster, more precisely without damage to the product and cleaner than any human could.