Pushing the Limits

With demands for over 300 meat patties packed per minute, flexibility in changing tray and a small footprint, can limits still be pushed?

Can Limits Still Be Pushed When Producing Food?

When it comes to food production, speed has always been key. The faster you can produce, the higher your ROI, but the road to high speed is not always an easy one and can be littered with different challenges.

Line size can be a problem as space inside productions can be limited and a production line can take up plenty of space. Not to mention the storage for thousands of trays needed.

With an everchanging market, with different demands, flexibility can become a challenge, as it can be slow and costly to adapt the production line to new standards, SKUs, or quantities of product.

However, challenges can lead to greater solutions. Our Packaging solutions are where speed, size, and flexibility have been the main driving force for developing a unique and exciting way to handle products.

The challenge for this customer was that they needed to run over 300 beef patties per minute with high precision and flexibility. To be able to change how many patties are in each tray, from 2, 4 to 6 patties per tray. All this with fast changeover times.

Furthermore, line size was something to take into consideration, as the production space was limited, and they were not able to store the thousands of trays needed for the production line throughput.

Challenges like this are one of the things we live for because it pushes us to think out of the box, explore new solutions and build something truly amazing. This is what we did.

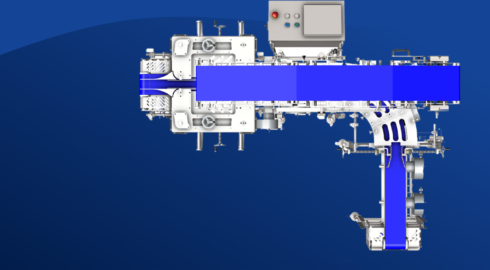

We managed to run more than 380 beef patties per minute neatly packed in trays. A feat we are proud of. All while still being able to change the denesting equipment on the fly to handle trays within the space that matched the customer’s needs.

To tackle the space challenge, we created an elevator, that feeds the denester at ground level from above, we were, not only able to save space building, but also made a solution where tray handling and food production are separated, making it even more hygienic.

This is a unique solution to a problem that many food producers know and face every time they wish to change or expand production. Demonstrating a challenge is but a solution away with the right partner. That’s why we at QUPAQ strive for quality and have done for 26 years as we have helped food producers around the globe, overcome challenges every day.