ANYTRAY Cleanline Buffer

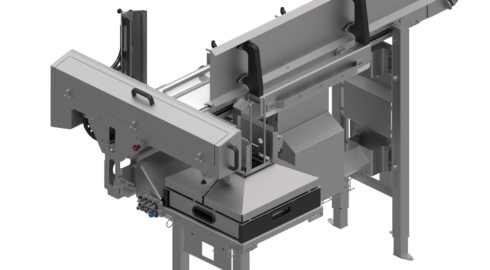

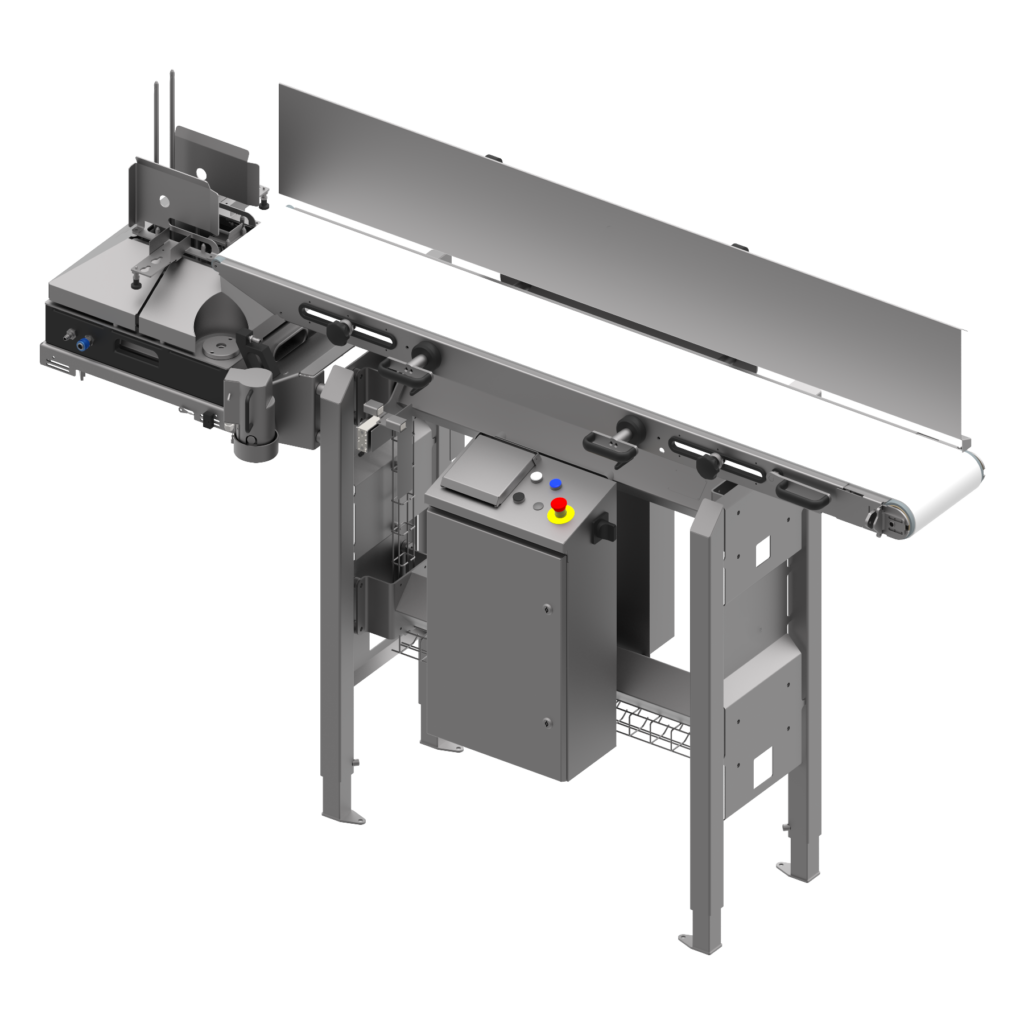

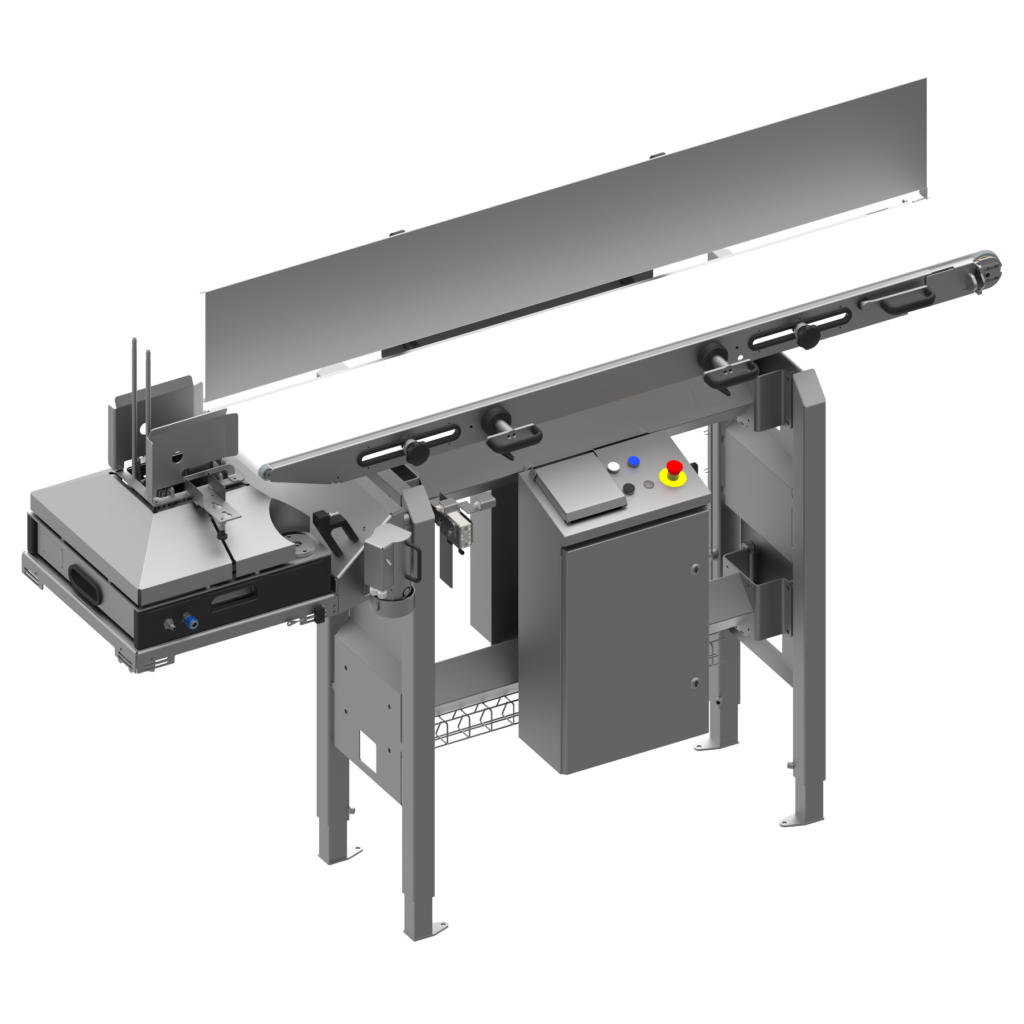

Experience uninterrupted production with the ANYTRAY Cleanline Buffer – an automatic denester and buffer solution designed to automatically denest up to 120 trays per minute.

ENCHANCE EFFICIENCY

Automate the Denesting Process

The ANYTRAY Cleanline Buffer is a denester and buffer solution made to consistently provide the ANYTRAY Cleanline Tool with trays at a speed up to 120 trays per minute.

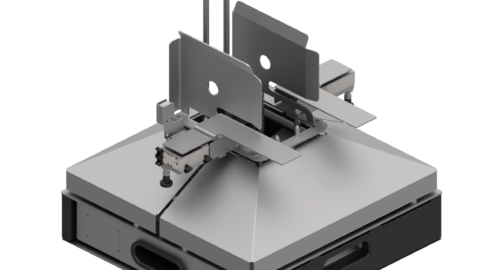

The automatic feeding of the ANYTRAY Cleanline Tool from a buffer of full height tray stacks results in less manual intervention and lower operating costs. This is also thanks to the easy, one-minute changeover from one tool to another that enables the machine to handle trays of various sizes and shapes.

Easy Integration with Low Maintenance

The ANYTRAY Cleanline Buffer stores and feeds full stack tray stacks into the denester automatically allowing for a continuous production flow and fewer stops. The ANYTRAY Cleanline Buffer is easily integrated into an existing production or packing line.

Handcrafted in Denmark using stainless steel, the ANYTRAY Cleanline Buffer features a cost-effective, low-maintenance, and hygienic design, ensuring reliability and efficiency in your production environment.

Technical Specifications

Weight of machine

Approx. 133 kg

Tray length – max length

360 mm

Tray width – max width

280 mm

Infeed height

1300 mm +/- 250 mm

Outfeed height

1300 mm +/- 250 mm

Power supply

1×230 VAC+N+PE

Power consumption

2.3 A

Max fuse

13 A

Frequency

50 Hz

Max short circuit current (Ik max)

6 kA

Voltage for valves

24 V DC

Air consumption

300L (120 trays/minute)

Air pressure

6 Bar

Operational temperature

32°F-95°F/0°C-60°C

Stock temperature

14°F-140°F/-10°C-60°C

Humidity

10%-90%

Noise level

< 80 dB (A)

Steel quality

EN 1.4301, AISI 304

Downloads

Three Reasons to Choose the

ANYTRAY Cleanline Buffer

HYGIENIC DESIGN

The hygienic design of the ANYTRAY Cleanline Buffer makes cleaning and maintenance easy and efficient. This ensures a clean production area.

FEW MOVING PARTS

The long-lasting design, built with few mowing parts keeps your production running smoothly with few production stops and low maintenance costs.

120 TRAYS PER MINUTE

Maximize your production capacity with high-speed, automated tray denesting. The ANYTRAY Cleanline Buffer has a capacity of 120 trays per minute.