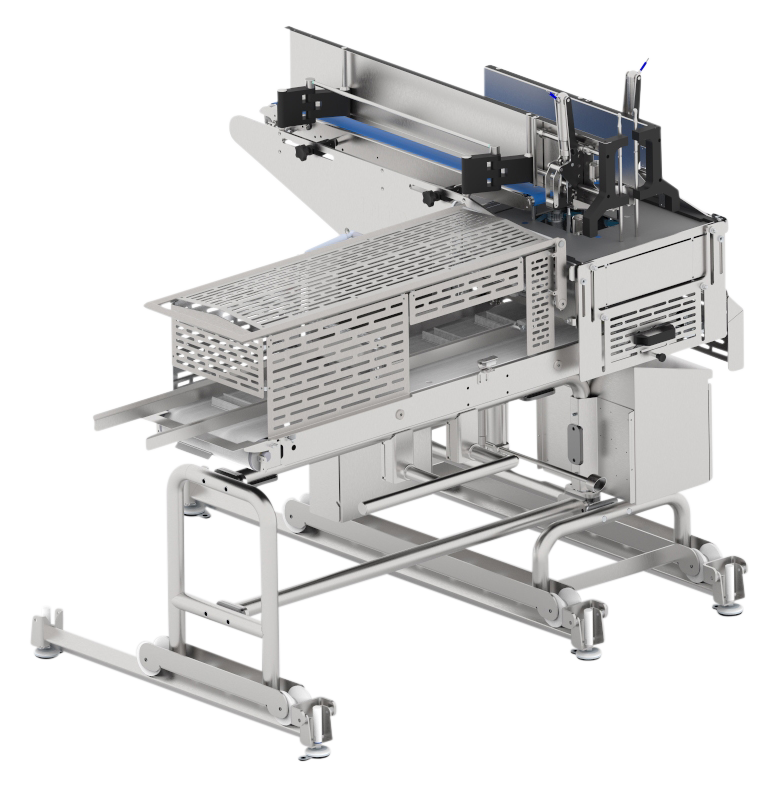

QUPAQ Step Conveyor

Unique step conveyor software allows you to place products in endless combinations, due to the complete placement control of the product in the tray

CAN STEP BACK AND FORTH

QUPAQ Step Conveyor

QUPAQ Step Conveyor is an automatic denester and conveyor that loads products into trays in steps with the integrated shuttle conveyor. It can load the tray step-by-step and if necessary also back and forth.

The QUPAQ Step Conveyor requires very little space compared to the volume and output.

Need of speed, but still need time to fill the tray? No problem. With our QUPAQ Step Conveyor we denest directly onto a conveyor band in steps. This means you will have time to fill in the trays – manually or with other machines – before the next tray drops and you fill the next tray with your minced meat.

The most flexible product loading line available. With the unique step conveyor software, you can place your products in endless combinations, due to the complete placement control of the product in the tray.

That’s fast, easy and clean.

Product Info

Highlights

Downloads

Three reasons to choose

INTRAY Step Conveyor

UNIQUE SOFTWARE

Can step back and forth and place the products in multiple rows and layers into the tray.

CAPACITY

Effective denesting and up to 100 portions per minute (tray depending).

EFFICIENT CLEANING

Open design and harsh environment ready that endures industrial cleaning (IP67 water protected).