Tray Denesters

Discover precision and efficiency with the best, fastest, and most versatile Tray Denesters on the market.

Leaders in Denesting Innovation

Get the Best Tray Denester

Explore our range of Tray Denesters, showcasing possibilities within our series: Cleanline, LeanOne, or Smart. The series either support pneumatic denesting, ANYTRAY, or electrical denesting, INTRAY. Whether you seek electric or pneumatic solutions, our portfolio offers a comprehensive array of Tray Denesters for fast, accurate, and reliable automatic tray denesting.

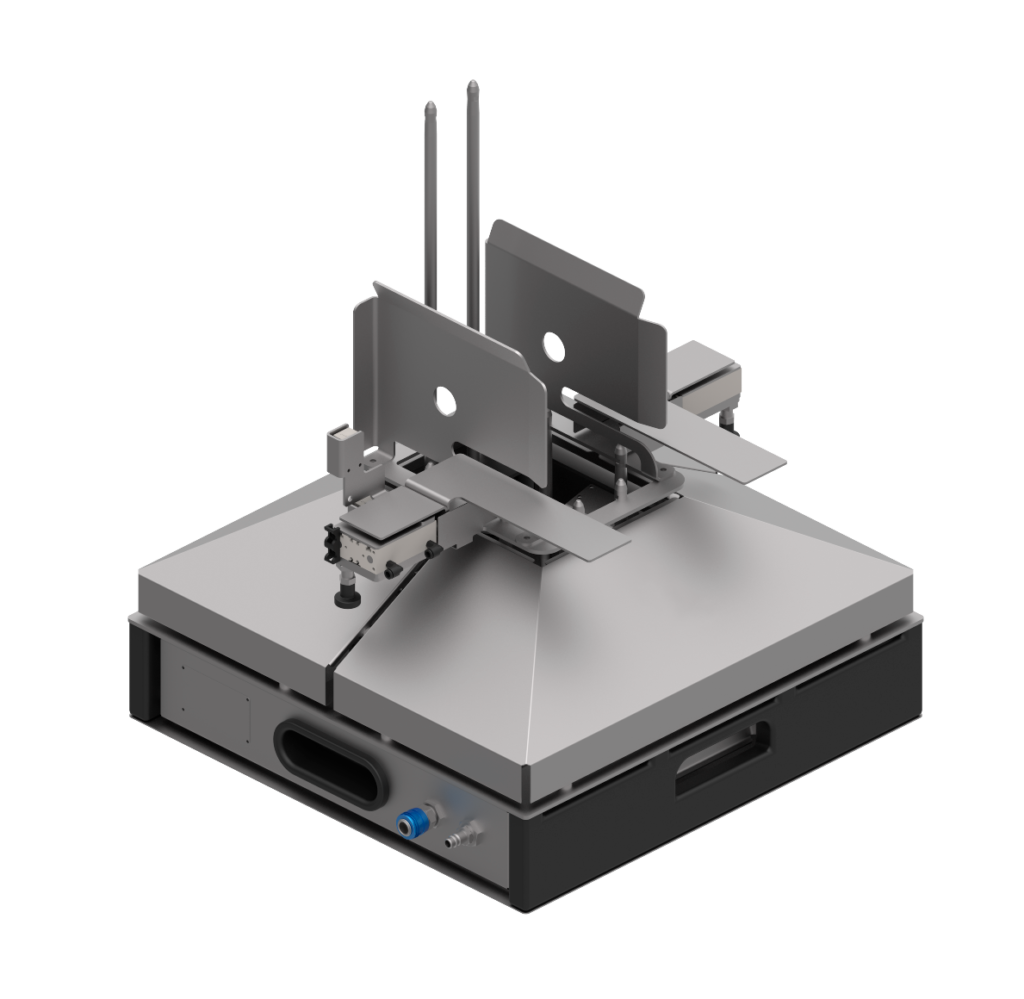

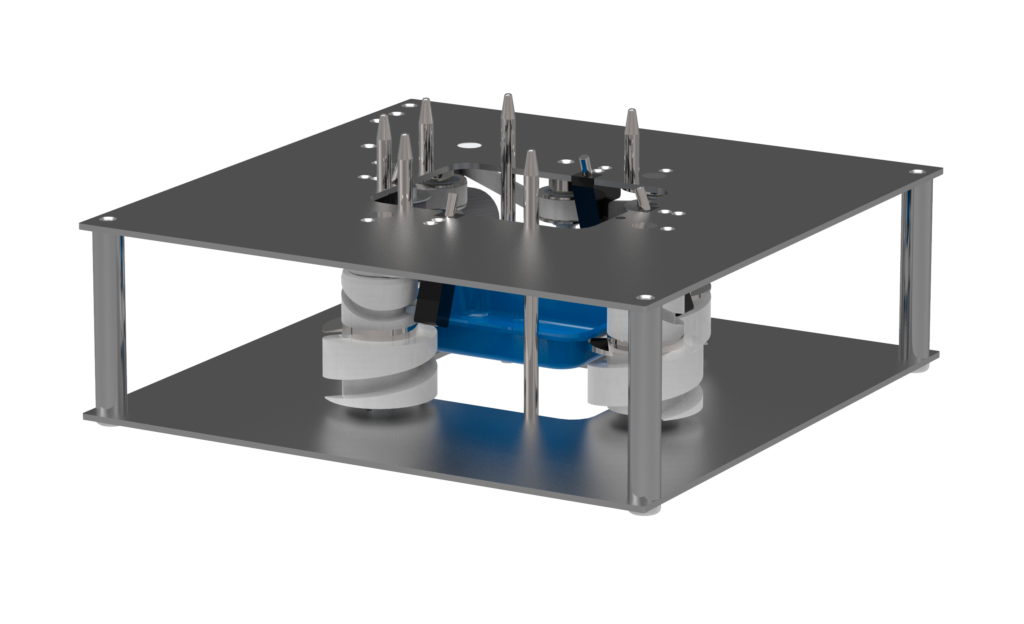

When selecting a denester, you will have to decide between a rack or buffer for feeding the denester. Your decision may hinge on space constraints, capacity requirements, or the preference to minimize manual intervention. You will also have to select the right Denesting Tool, to accommodate your trays. These tools will fit the form factor of either Cleanline, LeanOne or Smart depending on your needs and preferences.

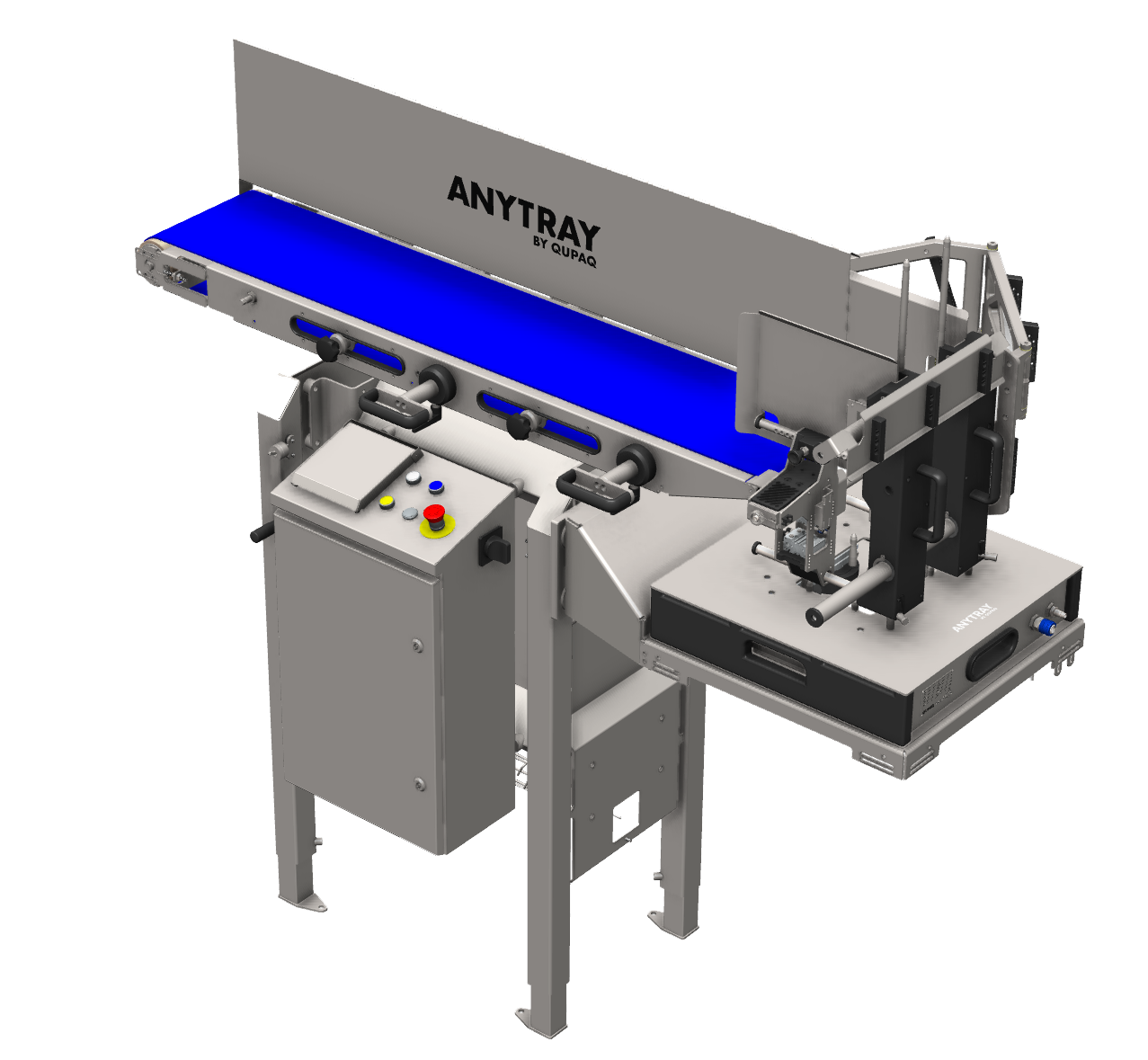

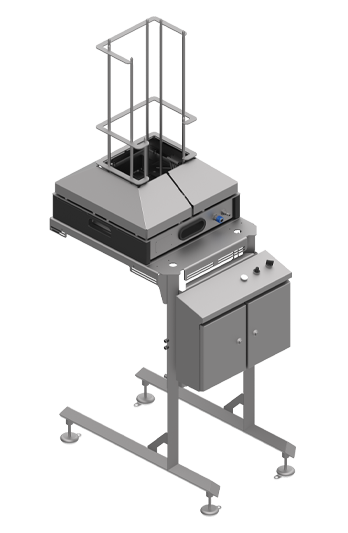

ANYTRAY Cleanline

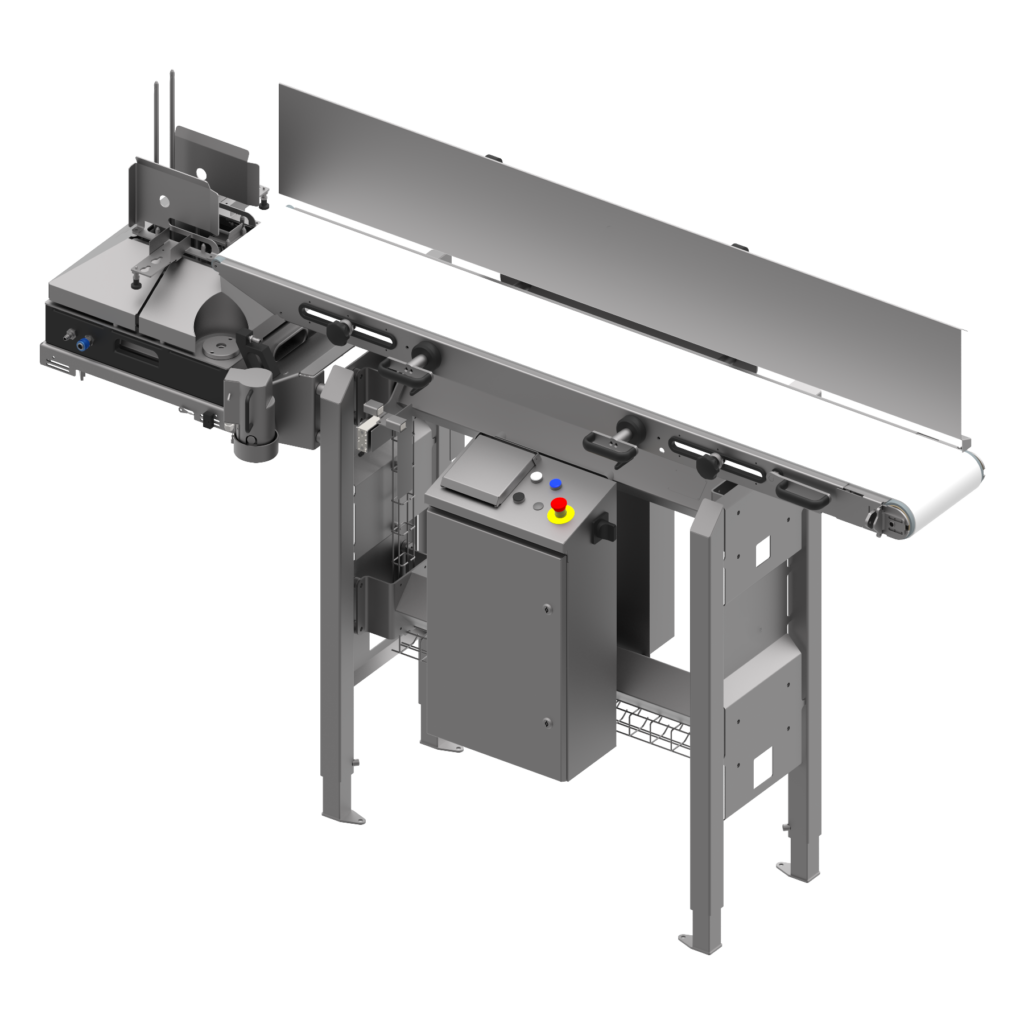

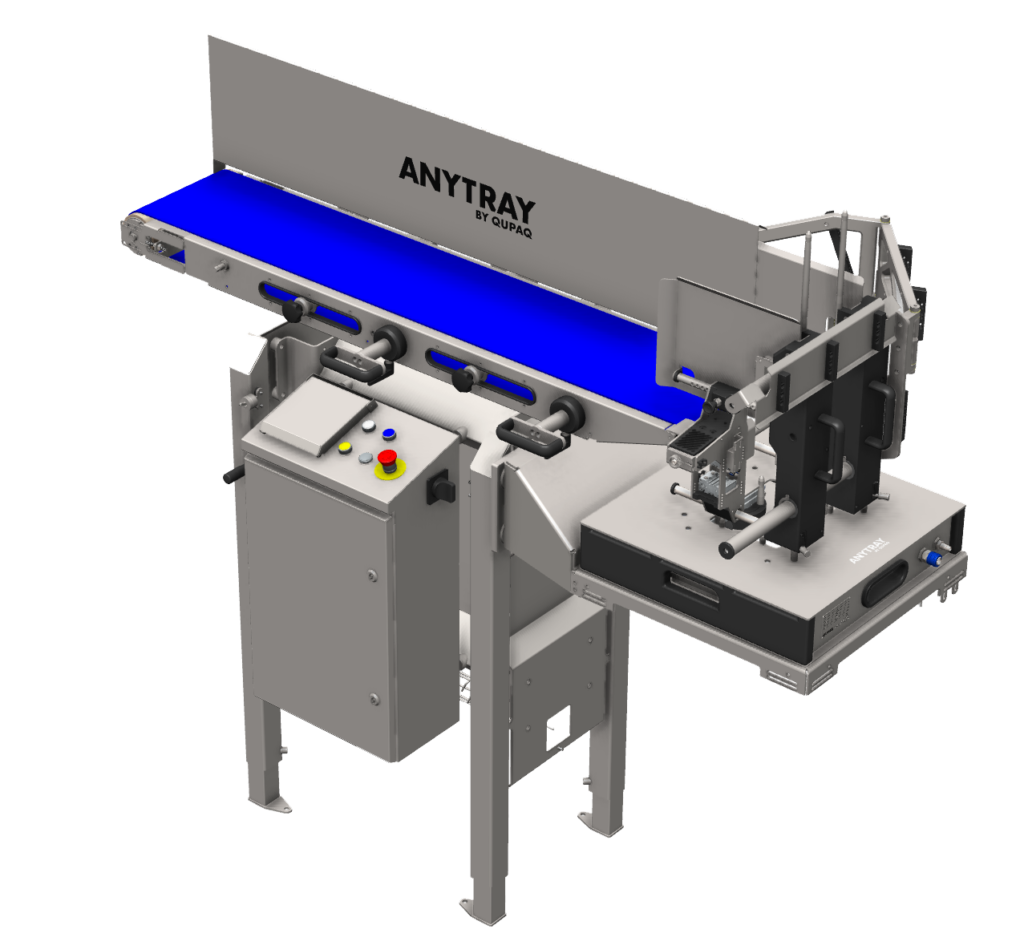

ANYTRAY LeanOne

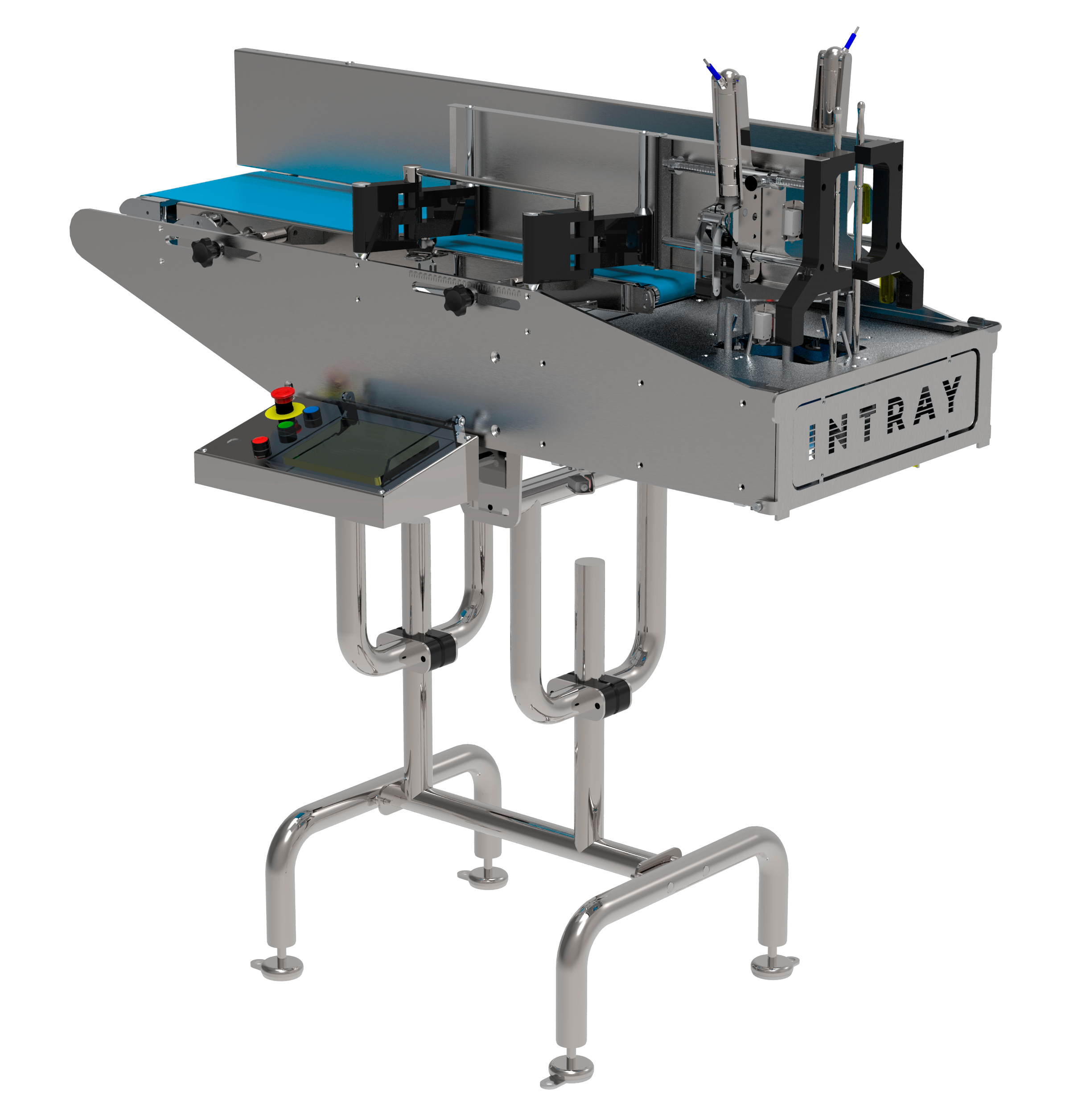

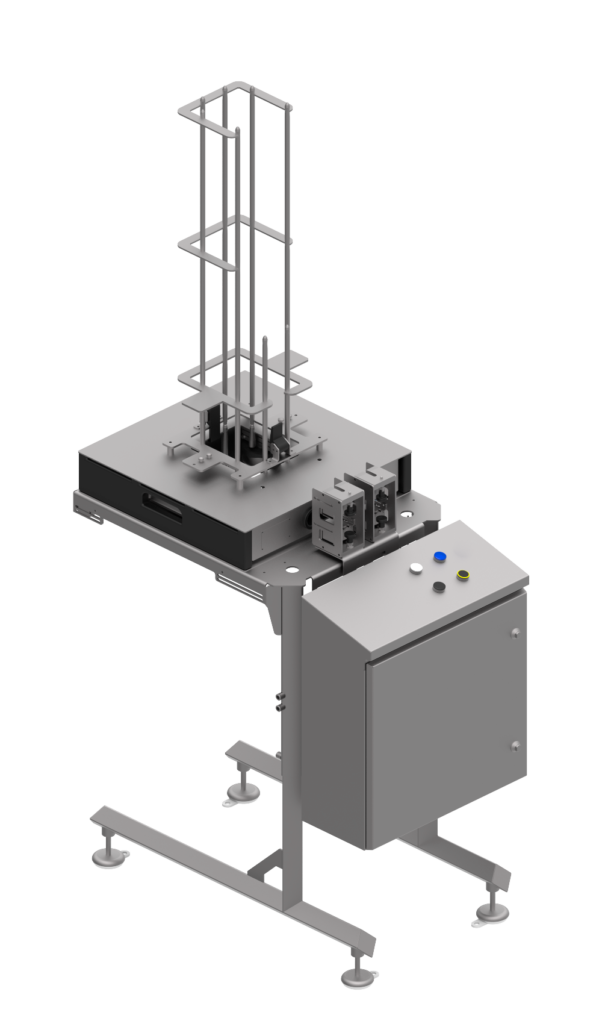

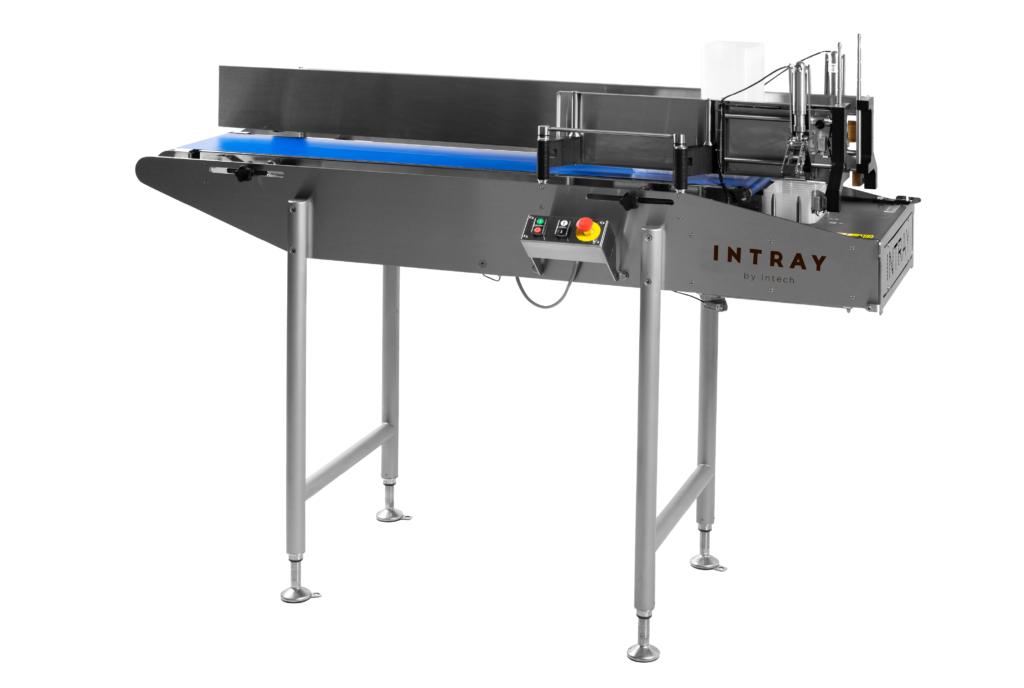

INTRAY Smart

Which solution is right for you?

Find the Right Tray Denester

Save Space With a Rack Denester

A Rack solution is the perfect choice for production lines in need of an efficient and automatic denester. The compact design of Rack configurations makes them ideal for facilities with limited space. Additionally, Rack solutions are well-suited for applications with moderate capacities, and they often become the preferred option not only for their space efficiency but also for the cost-effectiveness they bring to the table.

Embrace High-Capacity Automation With our Buffer Solutions

For high-capacity production lines demanding efficiency and reduced manual intervention, the Buffer solution emerges as the prime choice. Buffers automate the feeding process by handling multiple tray stacks, ensuring a continuous flow into the denester. This setup is particularly advantageous for high-speed operations and environments with significant production volumes. The Buffer solutions provide a hands-free denesting experience, making them the ideal solution for those aiming for top-notch performance and operational efficiency.

Plenty of Options to Suit your Needs

Additional options, including twin configurations, flatskin, or paperboard choices, along with servo-driven functions, can be explored within the categories above. Our modular approach enables tailored solutions to fit your production line requirements.

KEY NUMBERS

Quality Quantified

We know that the hygiene, efficiency, and reliability of tray denesting and handling automation

matter to our customers. But don’t take our word for it, take our numbers.

Our customers rely on QUPAQ to denest and handle over 10,000,000,000 trays annually. Bon appetit.

QUPAQ denest more than 2500 different tray types all over the world.

QUPAQ is the world leader in tray denesting and handling, and we’ve got the patents to prove it.