Food Manufacturing Labor Shortages: A Global Challenge

Efficiency is more important than ever as food businesses struggle to expand production volume in a time of economic uncertainty.

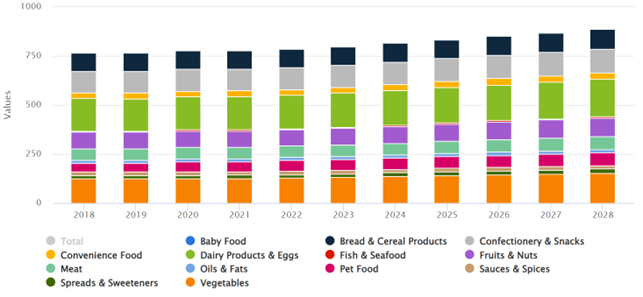

INCREASE IN THE GLOBAL FOOD PRODUCTION

The Importance of Efficiency

Efficiency is more important than ever as food businesses struggle to expand production volume in a time of economic uncertainty. Increasing processing costs, disrupted supply chains, and persistent labor shortages are currently challenging the food industry. With statistics strongly pointing to an increase in the global food production, the challenge of especially labor shortages will have to be met by food manufacturers if they want to also meet the increasing demands. But why are companies in the industry experiencing this decrease in employment, and how can they meet the obstacles it entails?

Global Food Production on the Rise

In a survey by Statista from 2023 it is predicted that the global food production will increase by 19% in the next five years. Therefore, the enormous demand for food products appeals to food processing factories to elevate production capacity.

However, with labor shortage having become a global challenge in the industry of food manufacturing, elevating production capacity can be a challenge to a lot of manufacturers.

Numbers from Statista show that the food volume will make a 19% increase from 2023 to 2028 (Statista 2023).

A Worldwide Challenge

In the U.S., despite unemployment being at historically low levels, around 750,000 jobs are vacant in the overall manufacturing sector according to Bureau of Labor Statistics’ reports. The extreme shortage is reflected in a study by Deloitte and The Manufacturing Institute who predict that a staggering 2.1 million manufacturing jobs will remain unfilled in the U.S. by 2030.

In the UK, food manufacturers also continue to be affected by labor shortages. According to the latest report from the Food and Drink Federation, it is revealed that in 2023, nearly 60% of food and drink manufacturers are seeing vacancy rates of up to 5%. Mid-sized businesses are experiencing the bulk of shortages in the sector, with around 50% reporting vacancies of up to 10% which is nearly three times the national average. So far, labor shortages are estimated to have cost food manufacturing businesses in the UK around £1.4 billion since July 2022 due to reduced production. Vacancies in the last quarter alone have cost the industry £192 million.

So, why is it that food manufacturers around the world are experiencing this decrease in employment?

Read also: Unleashing Cost Savings: The Power of Automation in Food Manufacturing

Understanding the Decline in Food Manufacturing Employment

Many complaints within the food industry about labor shortages have been linked to specific events, with Covid-19 being the most obvious example seen in a global perspective, whereas an event like Brexit has had a great impact in the UK.

It is especially the meatpacking industry that has been impacted by the labor shortage issue. Klaus Vestergaard, Facility Director at Himmerlandskød, the second largest slaughter/cutting facility of livestock in Denmark, gives his thoughts to why this industry is experiencing labor shortages:

“It’s getting harder and harder to get people to come into production. It is simply not a job for everybody to wake up very early in the morning or work all your shifts in a cold environment”.

However, Klaus has found a way to meet the obstacles that the industry is facing by investing in automation:

“In general, we have a hard time finding labor, so we must automate more of our work processes. Also, to be able to keep up with the increasing prices on the market, we can’t have high labor costs. Therefore, we need to cut down these costs, and we can do so by automating as much as possible.

Nevertheless, cutting down the labor costs does not mean that people are getting fired. “In fact, by automating certain packaging processes, we get to move manual workers to other departments. For instance, we used to have five people working at a packaging line. Now, we are down to two. The three other people have been moved to other departments at our site, where their labor creates greater value,” says Klaus.

Not only does Klaus believe the investment is a way of overcoming the issue of labor shortage, he also says that it enables Himmerlandskød to be saving money in the long term while increasing their productivity. As he firmly states: “There’s nothing to discuss. We can’t be part of the game if we don’t look into automation.”

Read also: Crafting the Future: Himmerlandskød Continues to Have Automation at Heart

Achieve More with Each Man-Hour

A survey from 2022 by the global software company UiPath also backs up that automation helps businesses like Himmerlandskød, and similar companies all over the world, avoid issues related to labor shortages. Despite struggling to recruit new workers, the interviewed businesses of the survey discussed how they were able to keep up with orders and reduce overall labor demand and costs. Therefore, by reducing the barrier to investment in automation, businesses are enabled to increase productivity and decrease reliance on manual labor. Additionally, the survey found that it can also improve the yield rates (ROI) of the existing workforce.

This is furthermore backed up by robotics expert and Technology Manager at the Danish Technological Institute, Søren Peter Johansen, who says that “companies that turn to automation are often able to optimize their processes which allows them to achieve more with each man-hour.”

Regarding the issue of labor shortage, Søren also points to streamlined production as a key point to choosing automation solutions: “Automation facilitates smoother production flow by mitigating disruptions caused by factors such as employee absenteeism. The reliability of machines ensures that production plans can be adhered to more effectively.”

Therefore, to be able to meet the demands of the elevating production capacity and to circumvent issues related to labor shortage in the food manufacturing industry, surveys, people working in the industry, and experts suggest that companies should begin to look more into automation.

Read also: Advancing Automation: The Future of Robotics