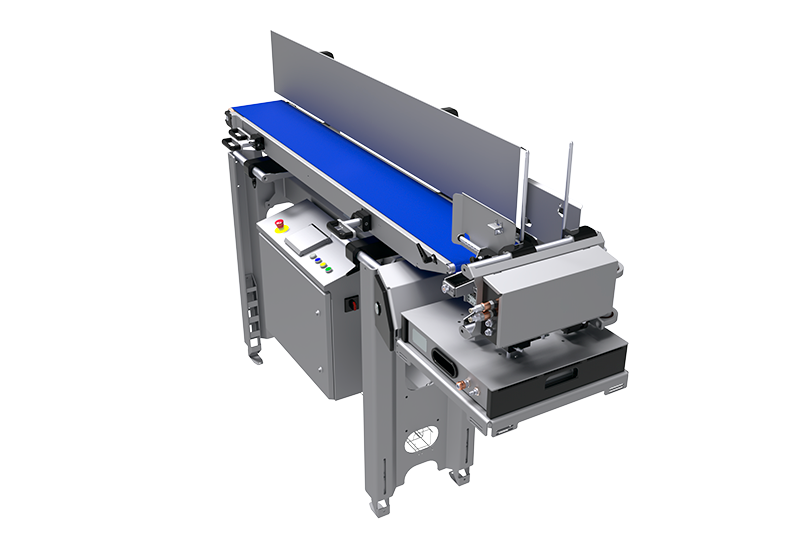

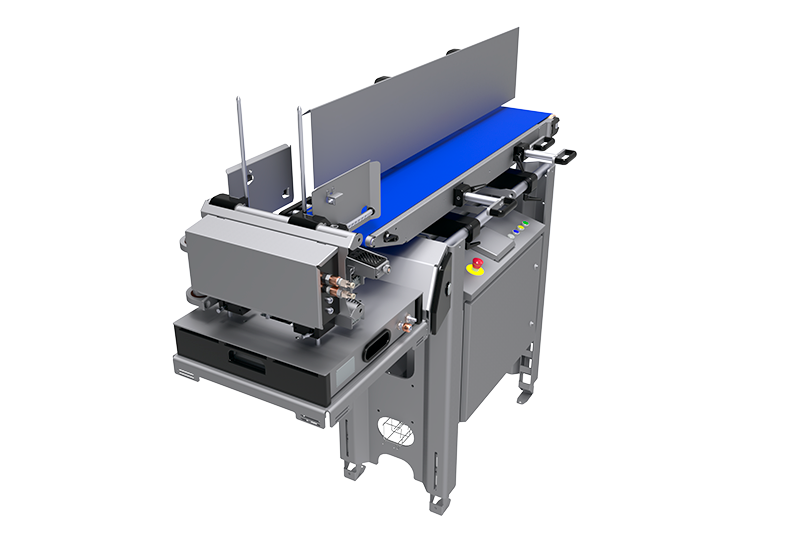

ANYTRAY LeanOne Buffer

The ANYTRAY LeanOne Buffer is designed to consistently provide the ANYTRAY LeanOne Tool with trays, at a speed of up to 120 trays per minute

ANYTRAY LeanOne Buffer

The ANYTRAY LeanOne Buffer is designed to consistently provide the ANYTRAY LeanOne Tool with trays, at a speed of up to 120 trays per minute.

The automatic feeding of the LeanOne denester from a buffer of full height tray stacks offers less manual intervention and lower operating costs.

Due to the gentle handling, the system can operate with trays in many different shapes and sizes that are made from all types of materials.

The LeanOne Buffer comes in three different lengths, making it easy to integrate into existing production/packing lines.

Introducing the new LeanOne series

Take a look at the LeanOne Buffer in action.

Technical Specifications

Weight of machine

Approx. 345 kg

Tray length – max length

360 mm

Tray width – max width

280 mm

Infeed height

1300 mm +/-250 mm

Outfeed height

1300 mm +/-250 mm

Power supply

3 x 400 VAC+PE

Power consumption

1.35 A

Frequency

50 Hz

Max short circuit current (Ik max)

6 kA

Air consumption

250 L (120 trays/min)

Air pressure

6 Bar

Operational temperature

32°F-95°F/0°C-60°C

Stock temperature

14°F-140°F/-10°C-60°C

Humidity

10%-90%

Noise level

< 80 dB (A)

Three reasons to choose

ANYTRAY LeanOne Buffer

INTELLIGENT CONTROL SYSTEM

The LeanOne buffer comes with an intelligent electrical control system that can handle many different types of trays, regardless of their size, shape and the material they are made of.

AUTOMATIC FEEDING

The automatic feeding of the LeanOne denester using the LeanOne buffer means less manual intervention and thereby lower operating costs.

HYGIENIC DESIGN

The hygienic design of the ANYTRAY LeanOne buffer makes cleaning and maintenance easy and efficient. This ensures a clean production area.