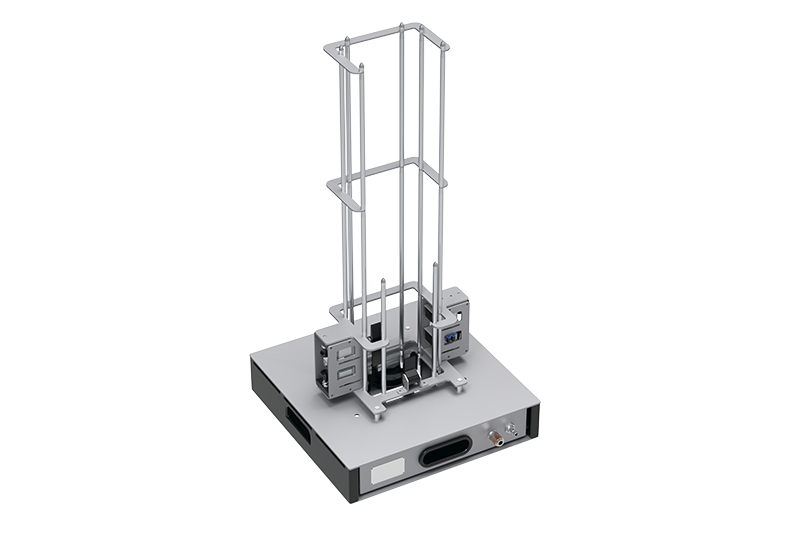

ANYTRAY LeanOne Tool

The ANYTRAY LeanOne Tool is an automatic denesting system that fast and accurately denests trays onto the production/packing line.

FOR RACK AND BUFFER

ANYTRAY LeanOne Tool

The ANYTRAY LeanOne Tool is an automatic denesting system that fast and accurately denests trays onto the production/packing line.

The system can handle up to 67% more trays per stack than other denesting products.

The compact LeanOne Tool provides an easy one-minute changeover from the most common tray type to the most specified type, making your production more efficient.

The innovative technology makes the LeanOne Denester applicable for both tightly packed stacks of trays as well as more fragile ones.

Watch the LeanOne series in action

Each ANYTRAY LeanOne Tool is custom made for one tray with specific length and width, but the ANYTRAY LeanOne Tool is able to handle trays of different material and depth.

Technical Specifications

Weight of machine

9.4 – 14 kg

Tray length – max length

360 mm

Tray width – max width

280 mm

Power supply

Air

Air consumption

300 L (120 trays/min)

Air pressure

6 Bar

Operational temperature

32°F-95°F/0°C-60°C

Stock temperature

14°F-140°F/-10°C-60°C

Humidity

10%-90%

Noise level

< 70 dB (A)

Steel quality

AISI 304

Three reasons to choose

ANYTRAY LeanOne Tool

EASY TO INTEGRATE

The LeanOne denester is easy to integrate into existing production/packing lines, regardless of what type of trays is used.

MULTIFUNCTIONAL

The lightweight denester can be used for both short- or wide edge leading. The same denester is used for buffer and rack solutions.

HYGIENIC DESIGN

The hygienic design of the ANYTRAY LeanOne denester makes cleaning and maintenance easy and efficient. This ensures a clean production area.