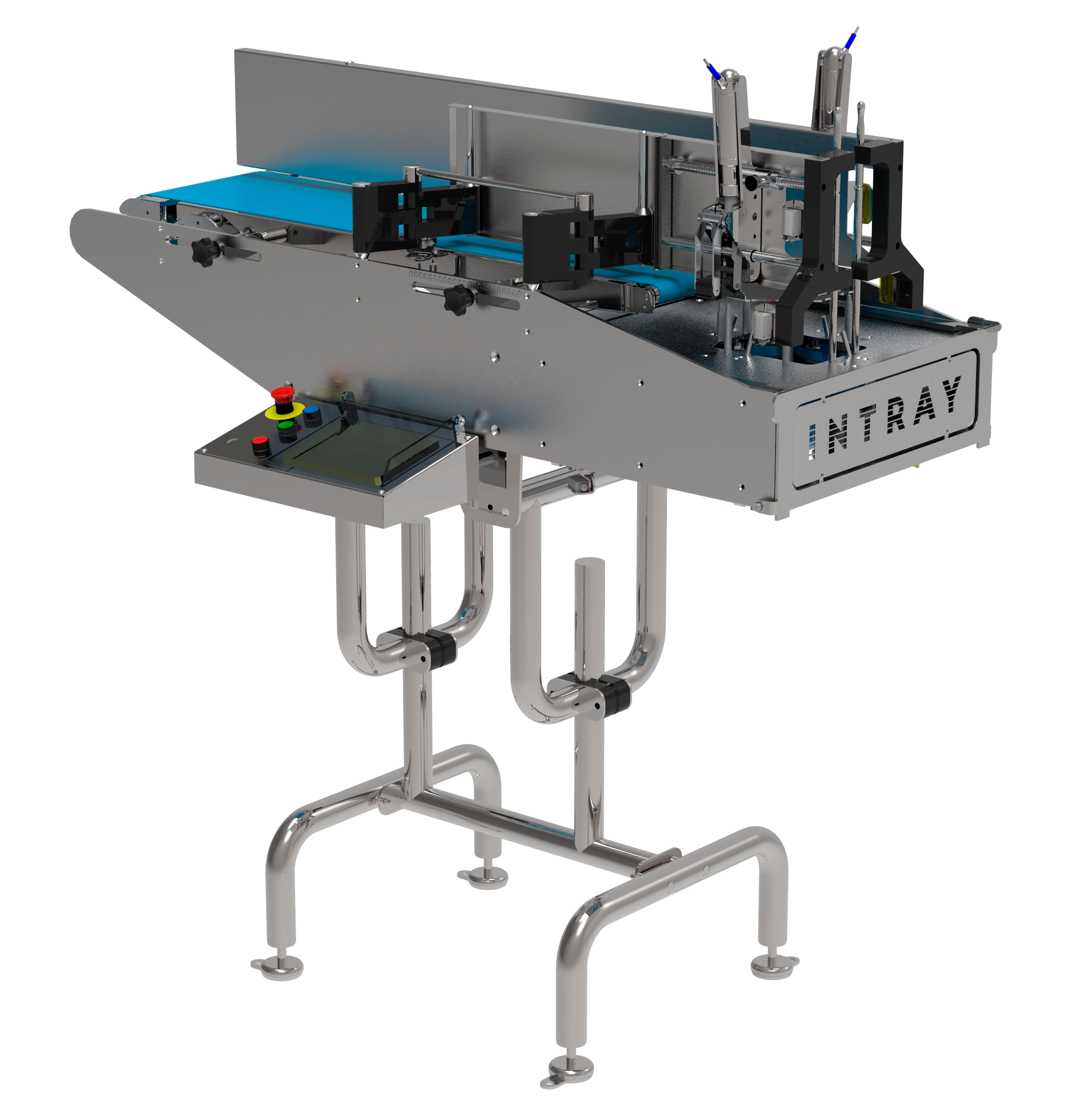

INTRAY Smart Buffer – Servo

Automatic loading of trays with advanced INPRO Software. Denesting errors become a thing of the past – speed of more than 200 trays per minute.

COMPLETE DENESTING CONTROL

Smart Buffer – Servo

The INTRAY Smart Buffer – Servo is the ideal solution for a fast-moving production line or a line with little manpower available for tray refilling. The tray conveyor is built into the Smart Stand, which saves a lot of space and provides autonomy and automatic loading of new tray stack to the denester.

Smart Buffer – Servo is delivered with a custom-made Smart Tool. As in all INTRAY products, the Smart Buffer – Servo has an easy to use integrated programmable control unit and can be easily cleaned. You also receive the time-saving Smart Tool. Using the Smart Tool, changing to a different tray is done in less than one minute.

Version 2 software for Smart Buffer – Servo

With the new version 2 software for the Smart Buffer – Servo, denesting has never been more efficient. The new intelligent software will i.e. automatically provide correction at denesting errors, which cut back on line stops and operators having to solve denesting errors.

Servo driven denesting

Your denesting is controlled by servo – giving you complete control of every stage of the denesting and freedom from not being dependent on compressed air. The Smart Tool is constructed to make it suitable to the tough industrial cleaning requirements in any food processing plant of today. INTRAY Smart Buffer – Servo gives you high autonomy, high speed and a highly reliable denesting solution in a very small space – fast, easy and clean.

Product Info

Highlights

Three reasons to choose

INTRAY Smart Buffer – Servo

INTELLIGENT SOFTWARE

Intelligent handling of tray faults. Backup to USB. Multiple operator access control.

COMPACT SOLUTION

Tray conveyor is built into the machine providing automatic loading of new tray stacks to the denester.

SPEED

The ideal solution for a fast-moving production line or a line with little manpower available for tray refilling.