QUPAQ Shuttle Conveyor

QUPAQ Shuttle Conveyor is used for multiple load of products. The capacity is up to 240 pieces/min

FLEXIBLE PRODUCT LOADING INTO TRAYS

QUPAQ Shuttle Conveyor

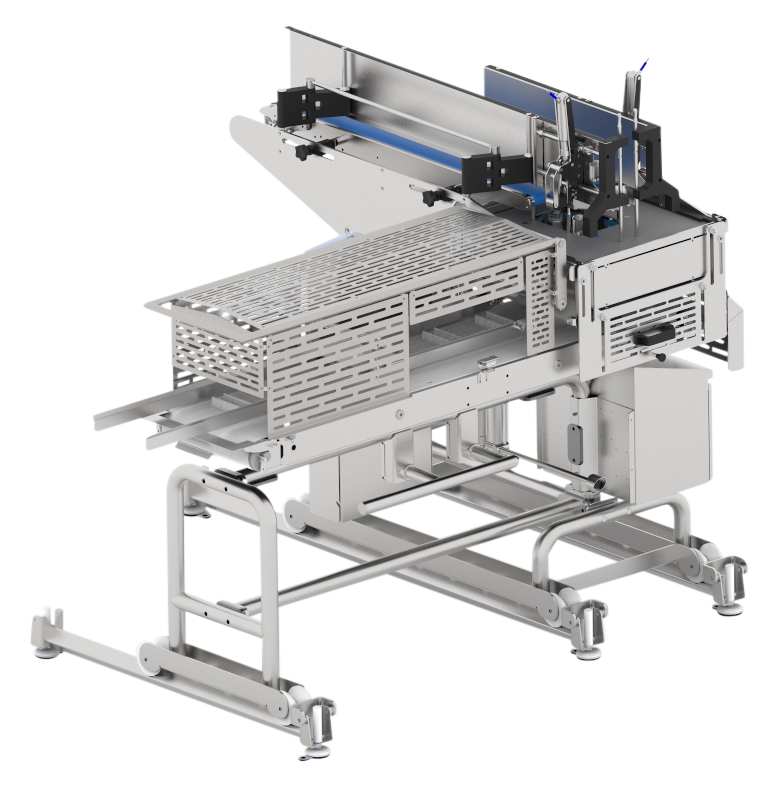

QUPAQ Shuttle Conveyor is used for multiple load of products. It is a versatile solution designed to streamline packaging automation. With a capacity of up to 240 products per minute, this conveyor system offers various loading and product aligning configurations.

Its retractable belt enables seamless loading of products directly into trays – this includes both single products and multi-product loading in steps. But the QUPAQ Shuttle Conveyor can be used for many different purposes and set ups. For instance, to align products from single-lane to multi-lane operations, simply by dropping down the products with the use of the retraction belt.

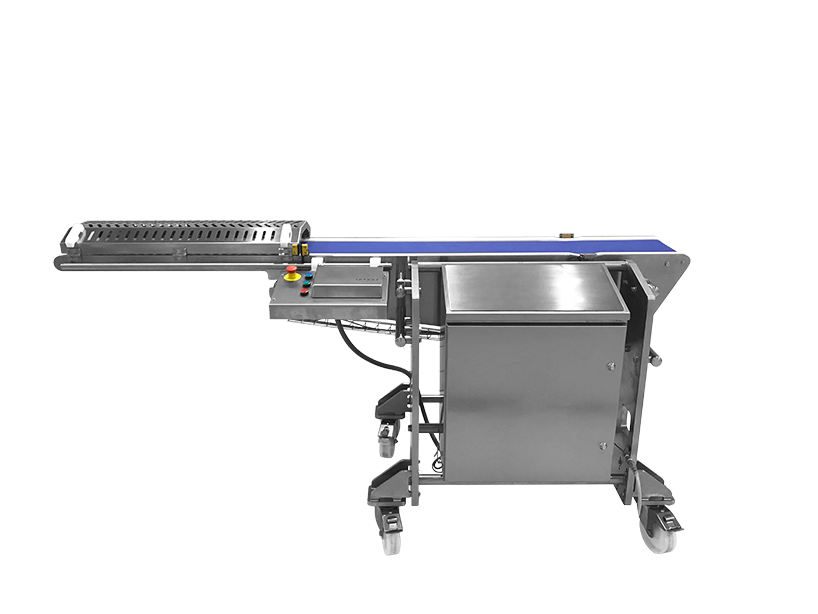

The QUPAQ Shuttle Conveyor can be adapted to most common filling lines. It has a hygienic design, and the removable conveyor band ensures easy cleaning. It comes with casters as a movable version or as fixed positioning.

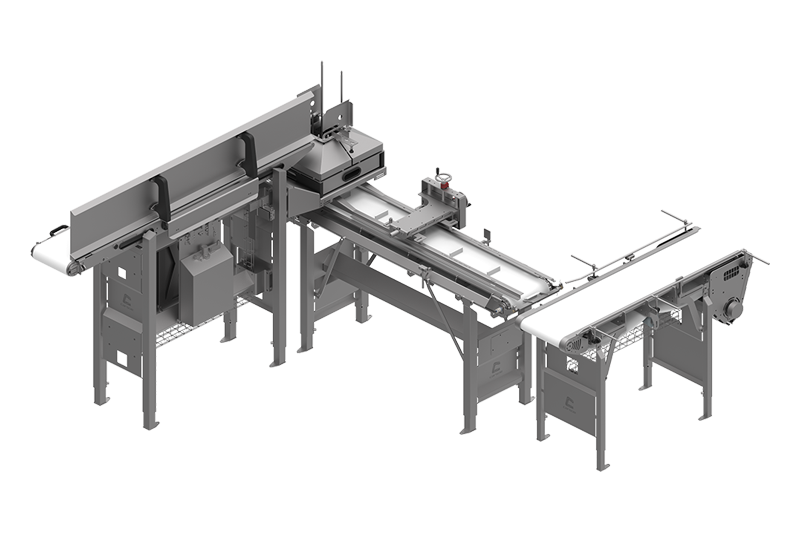

QUPAQ Shuttle Conveyor is highly usable in combination with:

– Step Conveyor

– Any kind of moving conveyors

– Freezing systems

– Packaging machines

The machine can be manufactured in different lengths and widths according to individual needs.

The QUPAQ Shuttle Conveyor offers a small footprint, which ensures an easy integration into any existing production setups.

Its hygienic design and removable conveyor belt ensure easy cleaning, while the option for casters allows for effortless mobility or fixed positioning based on operational requirements. Available in various lengths and widths to accommodate individual needs.

3 Reasons to Choose

QUPAQ Shuttle Conveyor

MULTI-FUNCTION

For flexible and multiple product loading into trays, onto paperboards or onto conveyor belts.

INCREASED FLEXIBILITY

Highly usable in combination with Step Conveyor, moving conveyors, freezing systems, and packaging machines.

HIGH CAPACITY

Up to 240 pieces/min (depending on product and loading pattern).

Product Info

Highlights

Technical Specifications

Weight of machine

Approx. 422 kg

Power supply

3×400V + N + PE

Power Consumption

0.425 kW

Frequency

50 Hz

Max short circuit current (Ik max)

6 kA

Steel quality

EN 1.4301, AISI 304

Capacity

Up to 240 products per minute

Air Pressure

6 bar

Air Consumption

0.1L/min at max.

Outfeed Height

990 mm (+/- 150 mm)

Infeed Height

1045 mm (+/- 150 mm)

Voltage for Valves

24 VDC