Is Food Production Getting Leaner?

Happy livestock on healthy grass and plenty of food for all. Is that now in the past?

Is Food Production Getting Leaner?

Many reports and news are coming out these days highlighting the issues at hand in the global Food Production industry and the breach in the supply chain. Some describe them as an unprecedented worldwide food crisis in the years to come.

Many food producing companies have specialized plants, that lies in the heart of the ecosystem they rely on. Its about the radius in logistics to keep a steady supply of ex. Produce and wares needed for production, reliable trays for packaging and a cost-efficient energy supply. If any of these steps in the supply chain gets disrupted the consequences can be vast. Both for the economy and the climate.

Also read: The world may be changing faster than your production line

And 2022 have been a challenging year for the industry. The wheat crop in US have been described as the lowest since 1963, whereas the population have grown 180%. In some states it has been reported that the number of cattle is down up to 50%. That number is difficult to cope with when predicting food prices in the years to come.

But it is a worldwide problem. Europe, Asia and Africa are all facing a severe decline in farming. For the most part due to climate change and droughts worldwide. We soon have to ask ourselves some difficult questions: How can we support a larger radius in the supply chain for the food industry, that is reliable and climate-friendly?

How Lean Can It Get?

With soon 8b people on the planet and the diminishing space available for reliable farming to support both greens and livestock we must rethink how food is getting produced throughout the entire value chain. Making production flexible and as cost-efficient as possible. Otherwise, prices will reach a point where the world population can’t afford to buy it, or the ecology footprint have too much of a negative impact on sustaining the production flow.

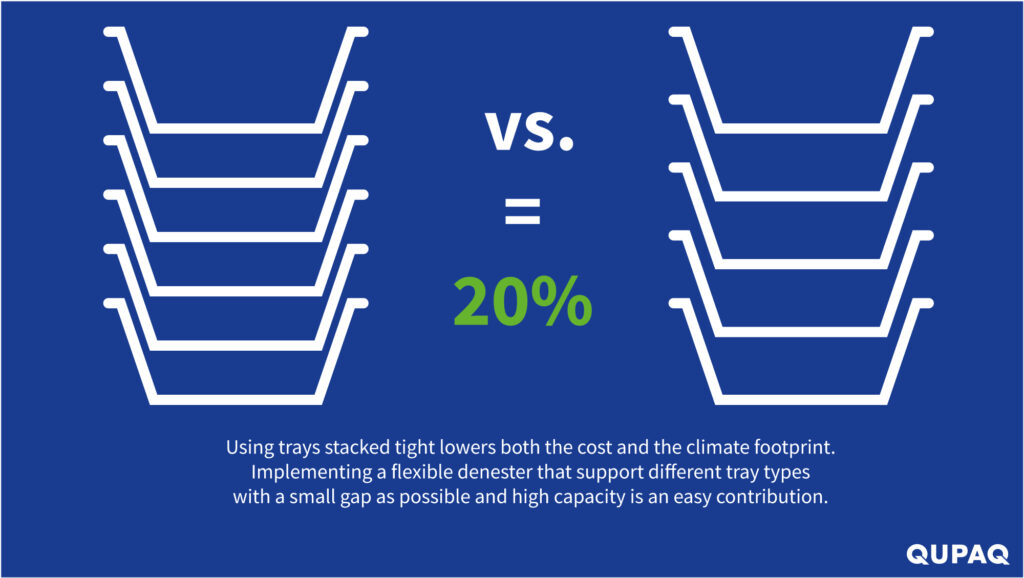

There are so many small things that can be done to start accommodating for the future. Increasing flexibility, changing to trays that can be stacked to a maximum and supporting many types of trays in the same equipment will make your production leaner and more able and agile for different products, markets and demands.

If the radius becomes too big for the supply chain to uphold the business model, we may see even more decentralization happening where larger plants are divided into several smaller plants. Having a proofed copy-paste template of a smaller fully automated production line requires strong reliable partnerships, that can build and implement for challenging layouts and environments.

Is Food Production getting leaner then? We may face challenges in the supply chain in the years to come, and if we take responsibility in solving the challenges, we can hope it is not the new normal. It will be if we don’t rethink the way we do things both business wise and climate wise.

Sources:

https://www.zerohedge.com/geopolitical/list-33-things-we-know-about-coming-food-shortages

https://bigthink.com/health/livestock-disruption/

https://www.rethinkx.com/food-and-agriculture