Exclusive Interview with Sealpac UK at Anuga FoodTec 2024

Get unique insights from Sealpac UK on their experience with the QUPAQ Flex Loader, showcased live at Anuga FoodTec 2024.

ANUGA FOODTEC 2024

Sealpac UK Shares Their Experience with the QUPAQ Flex Loader

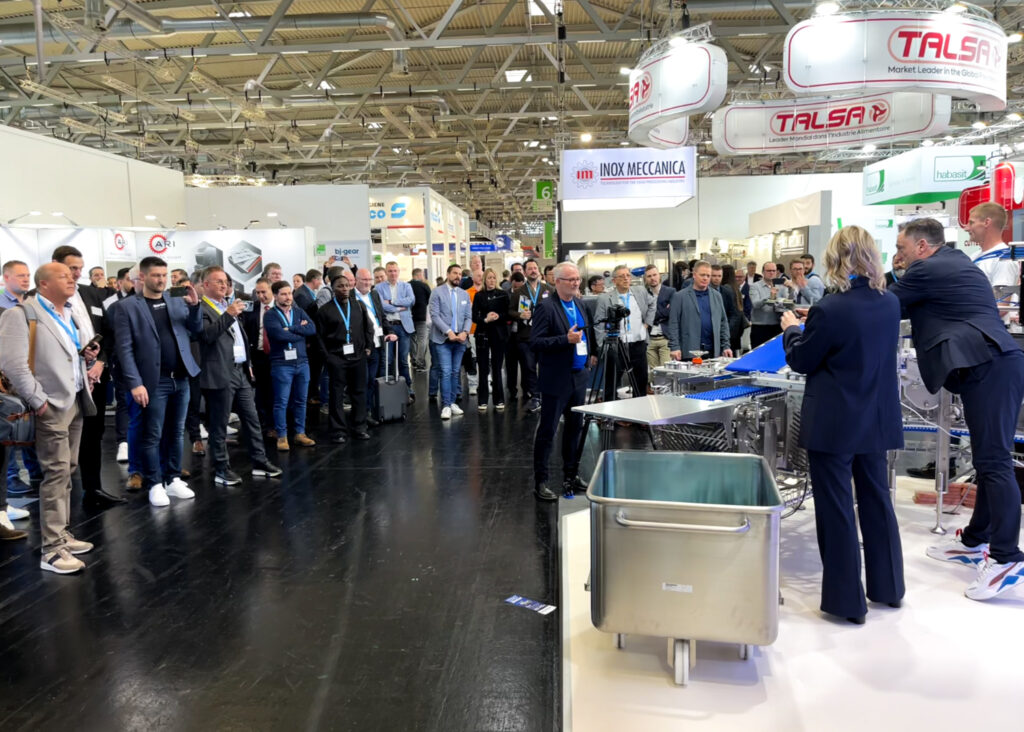

It’s been a couple weeks since the launch of the QUPAQ Flex Loader LIVE at Anuga FoodTec 2024. The event was a resounding success, with more than a hundred attendees from across the industry gathering to witness the capabilities of our latest innovation. Thank you to all who stopped by to watch the show!

Read also: ANUGA FoodTec 24: Our most Flexible Journey Yet

Working Closely With the QUPAQ Flex Loader

Following the unveiling of the QUPAQ Flex Loader, we welcomed John Lennon from Sealpac UK on stage for a 3rd party live interview. Sealpac UK has been working with the prototype of the QUPAQ Flex Loader for months at one of their customer’s sites. By working closely with the QUPAQ Flex Loader in action, John has gathered extensive experience and valuable insights about the performance and adaptability in real-life scenarios. Lucky for us, he agreed to share all his insights at Anuga FoodTec 2024.

In case you missed the interview, don’t worry – we have encapsuled the essential highlights of the interview below.

The Demand for Increased Flexibility

Sealpac UK’s had a customer seeking a solution that could adapt to their changing demands without compromising speed or efficiency. This was a solution already existing in the QUPAQ portfolio, but this customer needed to add the ability to run different products on the same line – ‘one machine to fit all’.

“The ROI is very attractive and helps our customers in achieving their long-term goals through automation”

In the interview, we asked John how flexibility is expressed at their customers’ sites today. He responded: “Today we run with 22 different recipes that require quick, simple, and seamless changeovers. The line runs with minced portions at a capacity of 120 per minute with extremely accurate loading of various sizes and weights. In addition to this, the line also runs with individual portions of steak – both naked and marinated- at a capacity of 106 per minute. These are shingled into various configurations.”

Despite these great results, both Sealpac UK and QUPAQ believe that the QUPAQ Flex Loader has the potential to run much faster with a capacity of up to 260 portions per minute depending on both product and tray type.

Going Slower to Run Faster

When we asked John to highlight the most important things about the QUPAQ Flex Loader on stage, he said: “We’ve moved away from the requirement of pneumatic stoppers for the loading position meaning a much more accurate and flexible loading position for the trays. The design means the trays are loaded flange to flange meaning the system runs naturally slower and more controlled to get a higher and more consistent output. Going slower to run faster is a strange concept, but the flexible nature of the machines makes it very appealing for high-speed, high volume or alternatively high-speed, high changeover frequency lines.”

“We have only used it for meat, but the QUPAQ Flex Loader can go into any segment really, and we have several projects in discussion already”

Why do you think it is important for modern food manufacturers to invest in equipment like this?

“Manufacturers are focused on delivering the best product at the lowest possible cost. Some of the tools in facilitating this are reduction of head count – labor, faster more efficient lines, and consolidation of lines to more flexible high-speed lines. The QUPAQ Flex Loader is a great machine for ticking these boxes. The ROI is very attractive and helps our customers in achieving their long-term goals through automation,” John says and adds: “We have every confidence in introducing this product to any customer on any food production line. We have only used it for meat, but the QUPAQ Flex Loader can go into any segment really, and we have several projects in discussion already.”

Thank you for sharing your insights at the event, John Lennon. Are you interested in hearing more about the project or the QUPAQ Flex Loader – then don’t hesitate to reach out to us or Sealpac UK.

More About Sealpac UK

“As a business, Sealpac UK have been focused on offering the best in full line solutions to the food industry for the last number of years. We utilize the best technologies available to ensure that we can deliver the most complex, flexible, and efficient line solutions available. Each piece of equipment or manufacturer we represent must complement our long-standing brands. The QUPAQ Flex Loader does exactly that. We have every confidence in QUPAQ and the QUPAQ Flex Loader,” John concludes.

…and vice versa, Sealpac UK !