More Food Safety, Less Waste

Ensuring food safety is crucial when it comes to meat manufacturing. Contamination at any stage of the packaging process can lead to significant issues, including foodborne illnesses, recalls, food waste, and financial loss.

Food safety & food waste

Minimize the Risks

In meat manufacturing, ensuring food safety is crucial. Contamination at any stage of the packaging process can lead to significant issues, including foodborne illnesses, recalls, and financial loss.

According to Statista, the US saw 4.05 million pounds of food recalled in 2023 under the USDA’s oversight. Here, recalls involving meat and poultry have surged by 85% since 2013, where a major contributor to these risks is manual handling during the packaging process.

Another critical issue in the food industry is food waste. Actually, according to the United Nations, 39 percent of all the food produced globally is wasted, of which 22 percent of all food never reaches the shelves in retail.

Risks of Handling Meat Manually

Both food waste and poor food safety can be caused by the risk of manual handling.

Manual handling of meat products introduces multiple points of potential contamination. Each time a worker touches the product, even when wearing gloves, the risk of transferring bacteria increases. Therefore, human error can compromise the safety of the product, potentially leading to foodborne ilnesses and food waste.

The risk of contamination and human error leading to food waste through manual food handling is especially high in fast-paced production environments, where high output is expected.

14% of all Food are wasted between Farms and Retailers, ie. in the logistic supply chain or the actual production.

3 Reasons Why Automation Is Key to Food Safety

Minimized human contact

Automation eliminates many of the risks associated with manual handling, reducing opportunities for contamination.

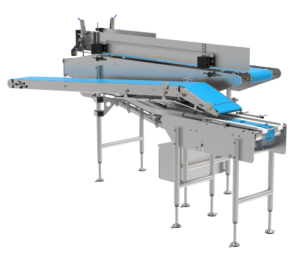

Enhanced packaging integrity

Automated systems ensure trays are denested and the meat is loaded securely and consistently, reducing the likelihood of damage or exposure to contaminants.

Improved production efficiency

Automation speeds up the packaging process, reducing the time meat products spend exposed to the environment.

Food safety & Food waste

Safer Packaging

At QUPAQ, we’re committed to helping food manufacturers reduce waste and improve sustainability through automation. As part of our ESG strategy, we have a particular focus on United Nations’ Goal 12: Responsible Consumption and Production.

By eliminating the risks of manual food handling, QUPAQ’s tray denesters and loaders help streamline the packaging process, reduce contamination risks, and maximize the use of the food we produce. This ensures that we minimize loss while the food we produce reaches more people.

One tray at a time, we are making food waste a thing of the past and food safety a priority for the future!

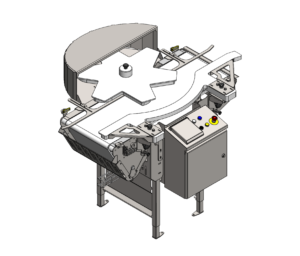

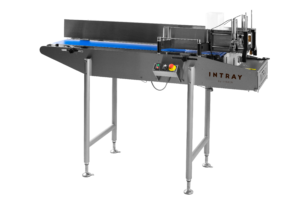

Our QUPAQ Step Loader takes up very little space on the line and have denesting and loading in one single unit. Add to that a very high throughput and capacity. In repetitive food manufacturing – Low Mix/High Volume – it is an outstanding unit that quickly insert the meat into a tray – plastic, foam, cardboard etc. – and ready for sealing or wrapping.

Keeping the product within open air for a very short time, and no human interaction with the meat, after is has been cut and processed, lowers risks of food waste and recalls.

No interaction with the product required

Packaging Done Right!

Improve US Meat Manufacturing

Meat manufacturing in the US faces a growing set of challenges. Market demand is rising along with population growth. Supply chains are becoming more complex, and labor shortages continue to increase. Altogether, this can make it harder for meat manufacturers to meet production needs.

What strategies have you considered for addressing these challenges?

Leaders in meat processing

Companies Using QUPAQ’s Technologies…