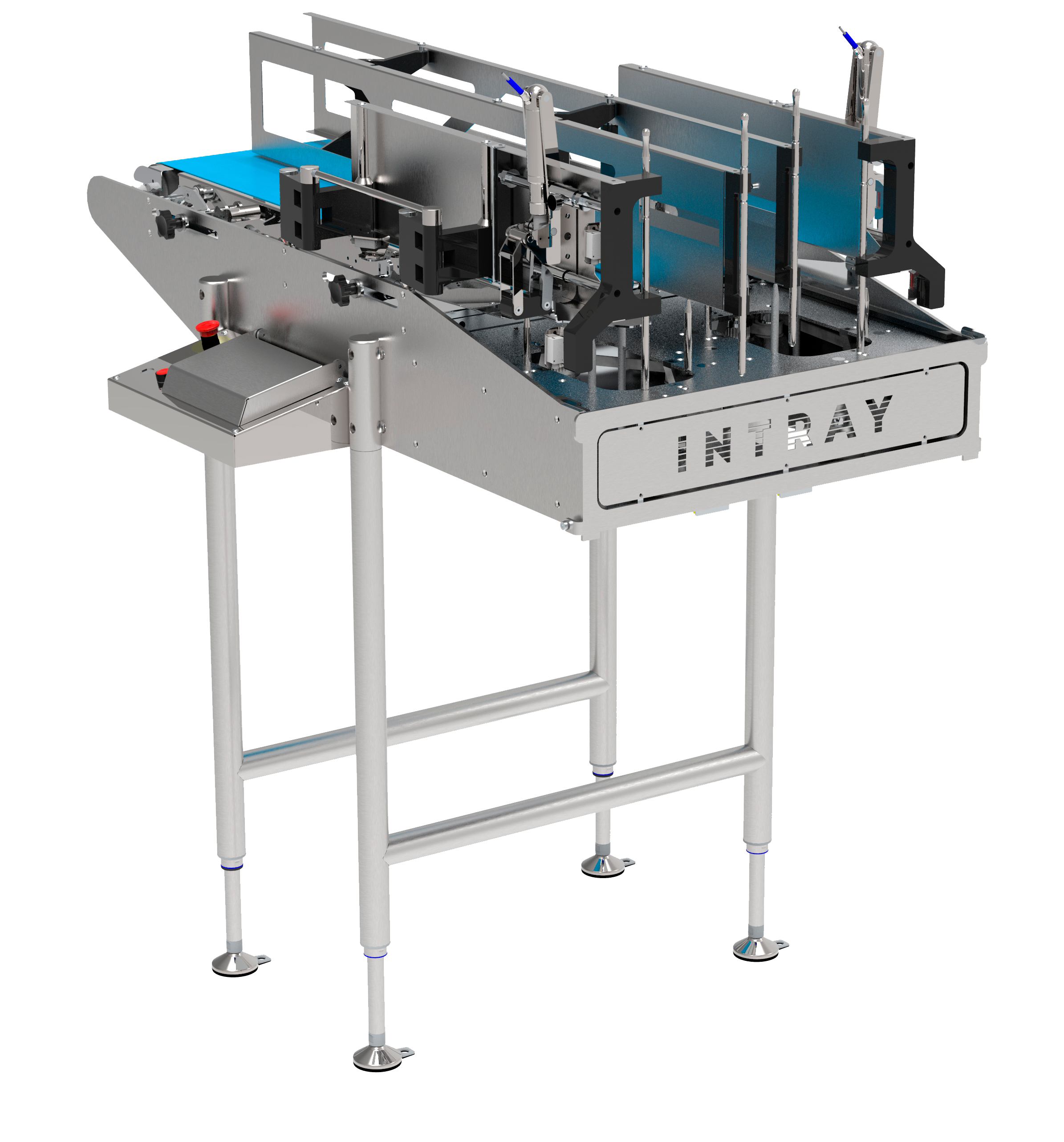

INTRAY Smart Buffer

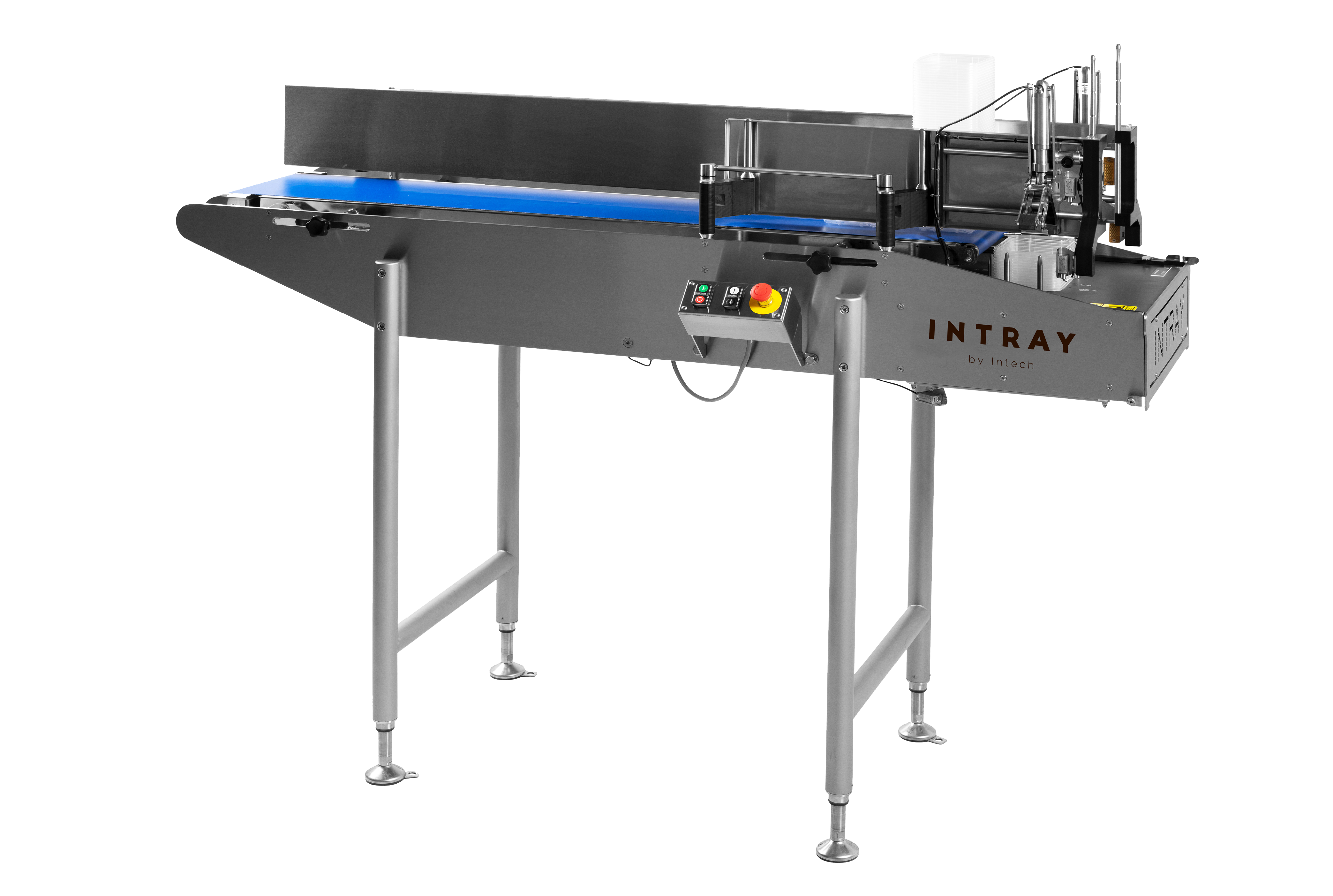

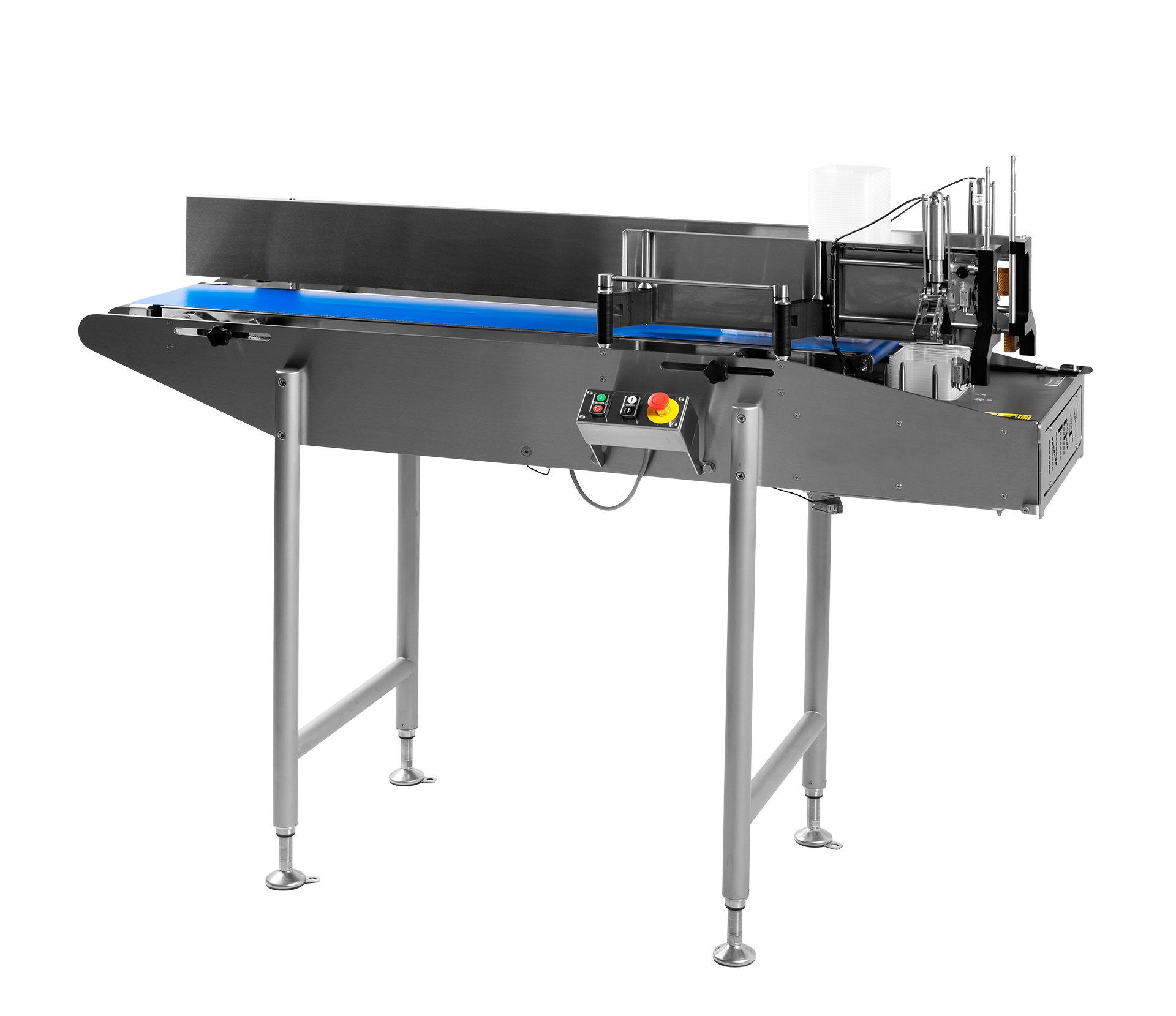

The INTRAY Smart Buffer is the ideal solution for a steady moving production line with a capacity up to 70 trays per minute.

Reliable Buffer solution

Automatic Electric Denesting

The INTRAY Smart Buffer is ideal for steady and continuously moving production lines with a speed of up to approximately 70 trays per minute. It is made for denesting on flat belts without flights.

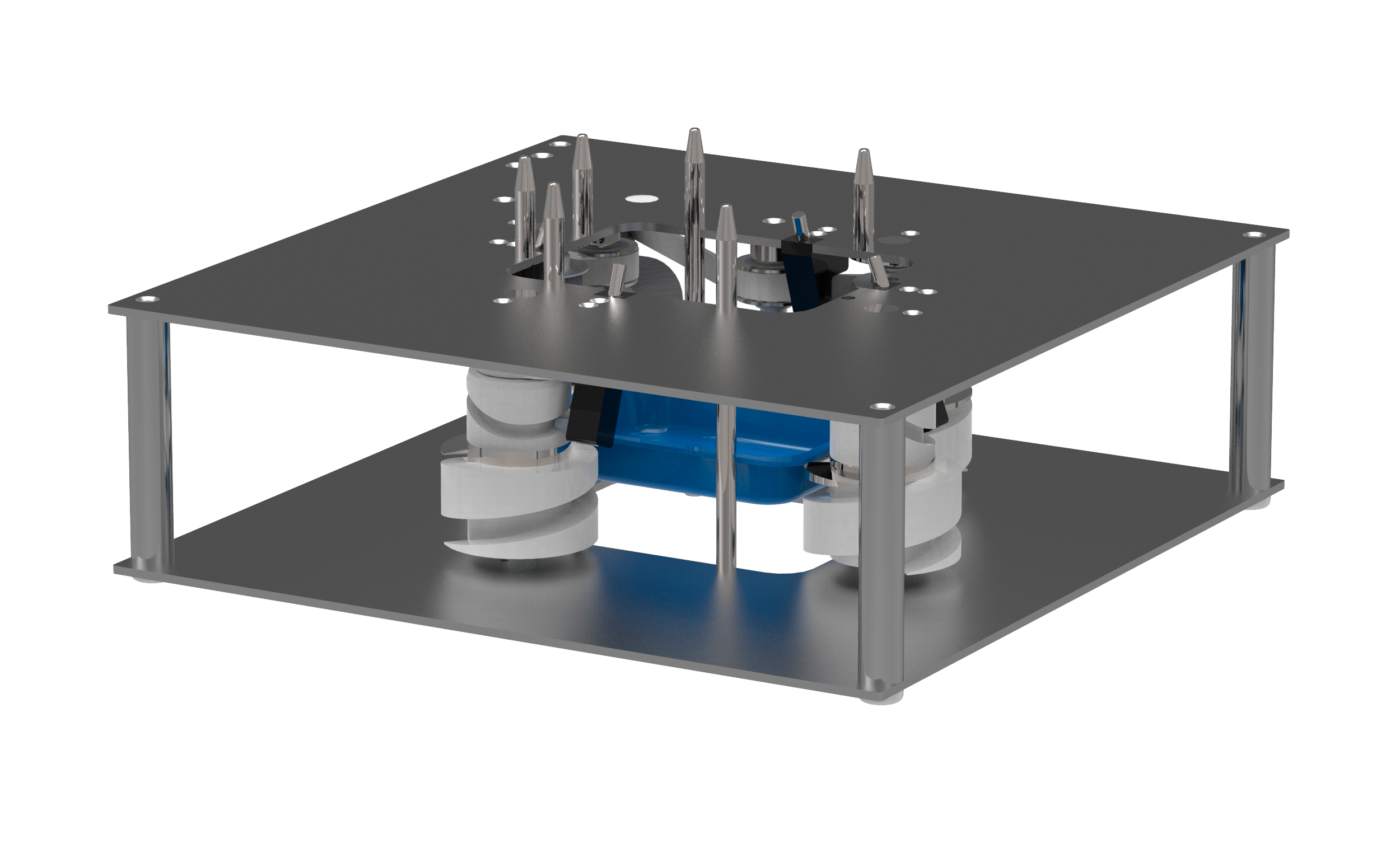

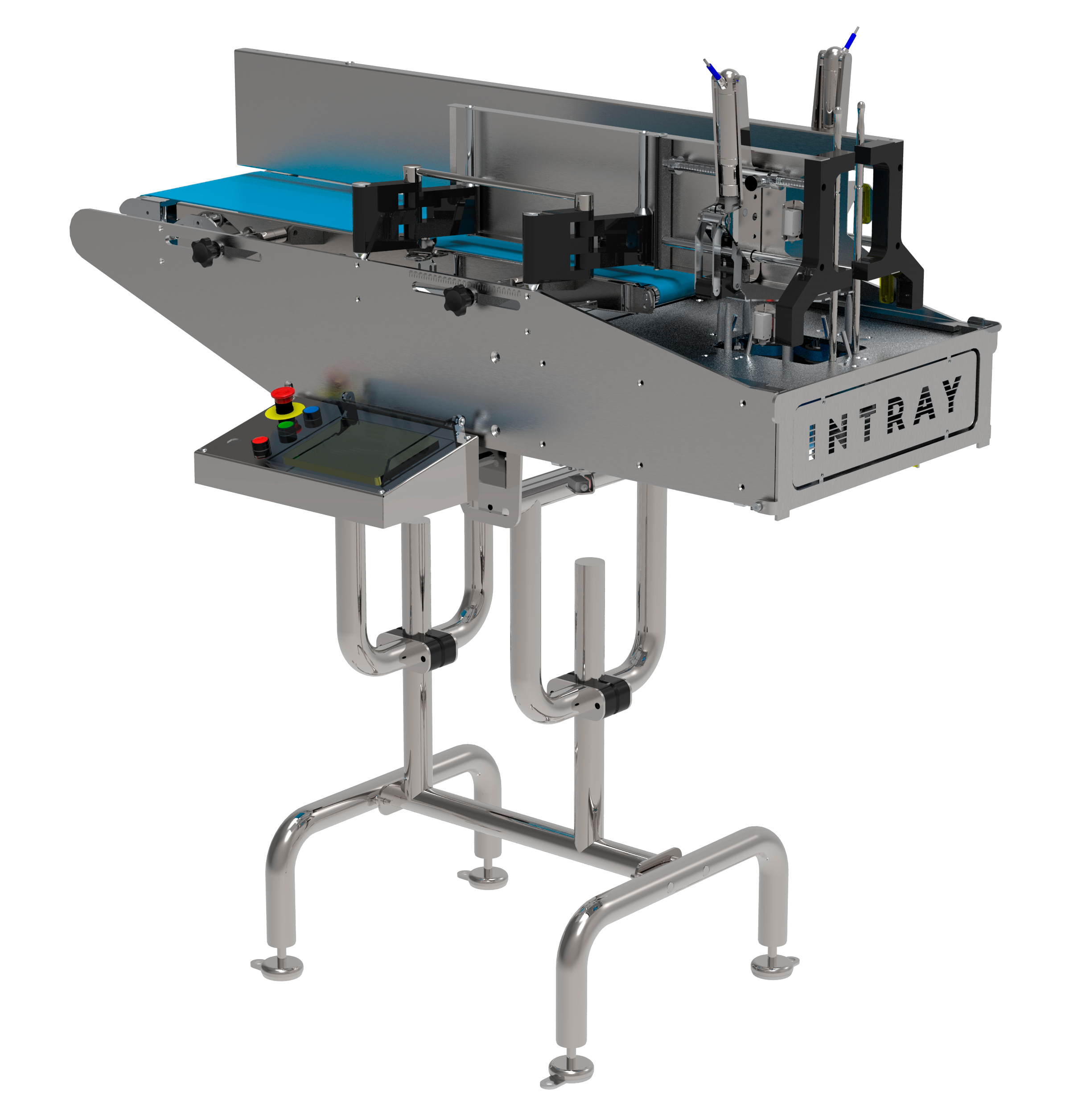

The tray buffer is built into the INTRAY Smart Buffer, saving a lot of space and provides autonomy and automatic loading of new tray stack to the INTRAY Smart Tool. By using the INTRAY Smart Tool, changing to a different tray is done in less than one minute. The buffer conveyor comes in variuos lengths depending on your space and preferences.

Space-saving Electrical Denesting

The denesting is controlled by an electric motor – providing controlled denesting and freedom from not being dependent on compressed air. INTRAY Smart Buffer provides electrical denesting at steady speeds and a highly reliable denesting solution in a small space.

Handcrafted in Denmark using stainless steel, the INTRAY Smart Buffer features a cost-effective, low-maintenance, and hygienic design, ensuring reliability and efficiency in your production environment.

3 Reasons to Choose

INTRAY Smart Buffer

Efficient Cleaning

The hygienic design makes cleaning and maintenance of both buffer and additional INTRAY equipment easy and efficient.

Easy Change-over

The solution is designed to ensure a quick switch between tray sizes, and still keep your production speed at the highest level.

100% Electrical

No compressed air. Complete denesting control with electrical driven denesting and a capacity of up to 70 trays per minute.

Product Info

Downloads

Denesting Tools

INTRAY SMART BUFFER Variants

Compare the Different Models

INTRAY Smart Buffer – Twin

The INTRAY Smart Buffer – Twin is a compact servo-driven denester with dual integrated buffer lanes, making it an ideal solution for high-speed production lines with limited space. It offers reliable denesting, and it minimizes line stops by automatically correcting denesting errors.