How Automation Eases Labor Shortage

Labor shortage is an increasing challenge in the business of food manufacturing, particularly in the meat industry.

Meat Production

The Effects of Labor Shortage

Labor shortage is an increasing challenge in the business of food manufacturing, particularly in the meat industry. According to the latest data from the US Bureau of Labor Statistics (2024), the unemployment rate in food manufacturing has averaged 3.8 percent over the past two years – a big drop from the 6.2 percent average over the past 24 years.

Labor shortages in meatpacking and food production present significant operational challenges, from increased costs to difficulties in scaling production to meet market demands.

Meat manufacturing companies are unable to find workers willing to perform repetitive tasks, particularly in environments like manufacturing sites. This means the companies must look for alternatives to maintain output.

The unemployment rate in US food manufacturing has averaged 3.8 percent over the past two years. This is the lowest in more than 20 years.

“We’re automating more of our processes. Not only does it help with labor shortages, but it also reduces labor costs, helping us stay competitive. Automating certain packaging processes has allowed us to reallocate staff to areas where their skills bring more value.“

Klaus Vestergaard

Facility Director, Himmerlandskød

3 Ways Automation

Can Help Combat Labor Shortage

Worker burnout and safety

Automation removes physically demanding or repetitive tasks from manual work, and allows workers to focus on higher-value tasks like food safety, quality control, and jobs that are not suited for automation.

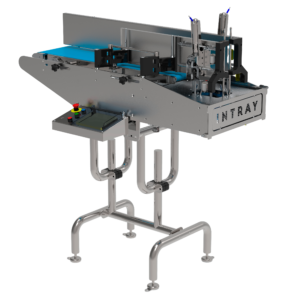

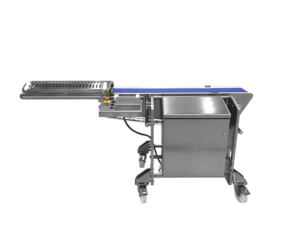

Less reliance on manual labor

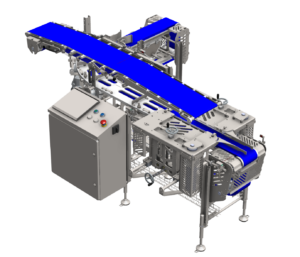

Automation facilitates more efficient production flow by reducing the risk involved with labor shortage. The reliability of QUPAQ’s machines makes it possible to follow production plans with greater effectiveness.

Cost efficiency

Automation offers long-term cost savings by optimizing processes. Companies can achieve higher productivity and capacity without proportionate increases in workforce size, and not adding further rolling costs.

Read More: Advancing Automation: The Future of Robotics

Automation as the solution

Address Worker Burnout and Safety

By automating tasks that are hard to staff, meat manufacturers can manage labor shortages, and moreover, help reduce burnout and improve workplace safety.

Workers often leave due to the monotony and physical strain of repetitive tasks. Automating such processes allows workers to focus on higher-value tasks, such as e.g. food safety and quality control, while reducing their exposure to physically demanding or hazardous environments.

By investing in QUPAQ’s plug-and-play solutions, you can eliminate the mundane, repetitive tasks that are difficult to fill and ensure your operations continue without disruption.

Products that make automation a no-brainer

Packaging Done Right!

Improve US Meat Manufacturing

Meat manufacturing in the US faces a growing set of challenges. Market demand is rising along with population growth. Supply chains are becoming more complex, and labor shortages continue to increase. Altogether, this can make it harder for meat manufacturers to meet production needs.

What strategies have you considered for addressing these challenges?

Leaders in meat processing

Companies Using QUPAQ’s Technologies…