Keep Up with Demand

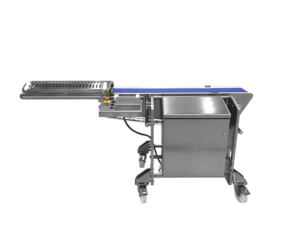

By eliminating bottlenecks caused by manual processes and reducing downtime, automation allows for increased production capacity without proportionally increasing costs.

Capacity and Scalability

Rising Demand for Meat

According to numbers from Statista (September 2024) the demand for meat in the U.S. will increase by 1.8 percent and on a global scale by 3.2 percent in 2026. For meat manufacturers, meeting this demand requires greater efficiency and production capacity. But to achieve that, operations must become more automated.

Automating tray denesting delivers substantial long-term benefits, including a positive return on investment. By eliminating bottlenecks caused by manual processes and reducing downtime, automation allows for increased production capacity without proportionally increasing costs. Therefore, as demand grows, your facility can scale more effectively.

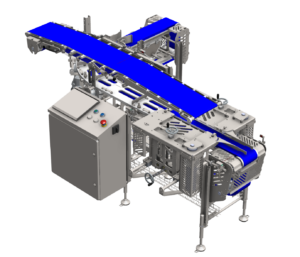

QUPAQ’s solutions allow for modular scalability, meaning your production capacity can grow in line with demand. Whether you are expanding existing lines or adding new ones, automated tray denesting, loading, and handling solutions can help you increase throughput while reducing downtime, which helps making your facility ready for future demands.

Read more: Top 5 Reasons for Downtime in Food Manufacturing

The demand for meat in the U.S. will increase by 1.8 percent and on a global scale by 3.2 percent in 2026.

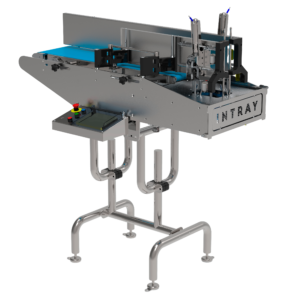

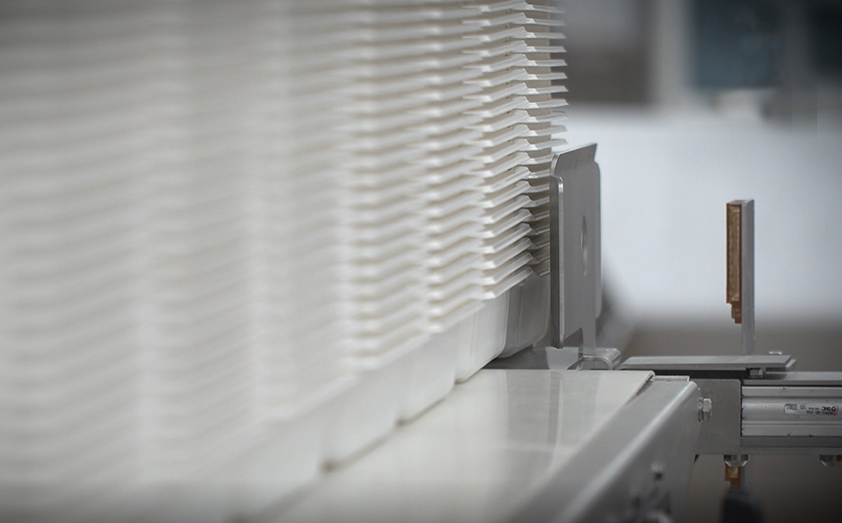

3 Ways QUPAQ’s Denesters Increase Uptime

Denesting Success Rate

QUPAQ’s tray denesters have a remarkably high success rate, which ensures that trays are accurately placed without interrupting the flow of production.

Flexibility and efficiency

QUPAQ’s tray denesters are designed to handle multiple tray formats on the same line and equipment, offering flexibility while maintaining high efficiency. This versatility ensures that your production line can easily adapt to various packaging needs without the need for frequent adjustments.

Reduced manual intervention

By automating the repetitive task of tray denesting, you can significantly minimize the risk of delays caused by errors during manual handling or employee absenteeism, which often disrupt production schedules.

If you already have a tray denester

Uptime Management

Tracking the performance of your tray denesters can provide valuable data and insights. By monitoring success rates, you can quickly identify any emerging issues, understand the consequences they may have on overall production, and implement solutions to further optimize your uptime.

This proactive approach not only ensures continuous production, but it also helps you to fine-tune your processes, which can make your operations more resilient and adaptable to changing market demands.

Read more: Avoid Downtime: Log and Monitor Tray Denesting Success Rate

Products that are fast and scalable

Packaging Done Right!

Improve US Meat Manufacturing

Meat manufacturing in the US faces a growing set of challenges. Market demand is rising along with population growth. Supply chains are becoming more complex, and labor shortages continue to increase. Altogether, this can make it harder for meat manufacturers to meet production needs.

What strategies have you considered for addressing these challenges?

Leaders in meat processing

Companies Using QUPAQ’s Technologies…