The Machine That Denested 1,094 Trays in 60 Seconds

We wanted to use off-the-shelf equipment with very little modifications

THE LITTLE DENESTER THAT COULD…

World Record: 1,094 Trays Denested in 60 Seconds

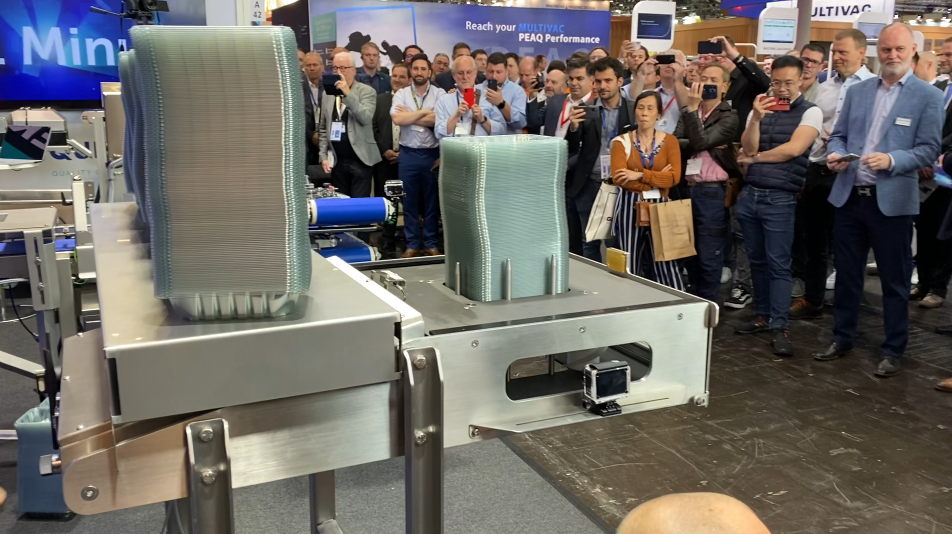

On Friday May 5th, 2023, QUPAQ set a World Record within tray denesting. We did that live at interpack 23 – the biggest trade fair in Europe within Food Manufacturing. But why did we do it, and what has happened since?

Ever since we returned home from interpack 23 with a World Record – 1,094 trays denested in 60 seconds – we have been met with many questions and comments about this feat. The response has been quite overwhelming, with so many of our partners and customers congratulating us.

Also read: QUPAQ sets a wild world record at Interpack 2023

Not about Speed

Speed is not the main KPI or bottleneck of a tray denester. As the world’s leading vendor of tray denesting machinery we of course know that. Most tray denesters can already run faster than the other machinery needed on a production line. This could be tray sealers, processing technology and end-of-line equipment. Even basic conveyors.

As many have clearly pointed out: No company is about to run 1,000+ trays per minute on a single line. But that is not what this record is about.

Reliability above All

When we decided to set a world record, we already knew it would be a challenge. To be honest, we weren’t convinced if it would be possible at all. Of course, if we custom built everything and designed the perfect tray for the attempt, everything is possible. But we wanted to use off-the-shelf equipment with very little modifications.

The little denester that could. It was an INTRAY Smart Stand Servo with minor customizations. We also added a shelf on top for trays waiting to be loaded and made holes in the frame so people could look directly into the tool and see what was happening.

We quickly decided on using an INTRAY Smart Stand Servo for the attempt. There were changes made to the gearing to reach the speed needed. Our main concern was the denesting tool – the Smart Tool. We had to make absolutely sure, that no tray errors would surface during the attempt.

Thinking Differently

Building this machine forced us to think in other ways, and everything had to do with reliability.

Also read: Avoid downtime: Log and monitor tray denesting success rate

The way the tool was constructed – especially the screws – is innovation at its highest. We did some things with this tool that will also be seen in the commercially available Smart Tools we are building right now, and for new tooling concepts still to come. This teaser is placed here on purpose.

Next Problem: Gravity

After the machine was designed it was time to consider if trays would be able to release the tool fast enough before the next tray in line would come.

This has to do with gravity. At this speed, when a tray exits the tool, it actually slows down in mid-air, as the denesting tool works at a much higher acceleration and speed, than gravity alone is able to pull. This would make the trays renest mid-air. Remember, we are talking about 18.23 trays per second!

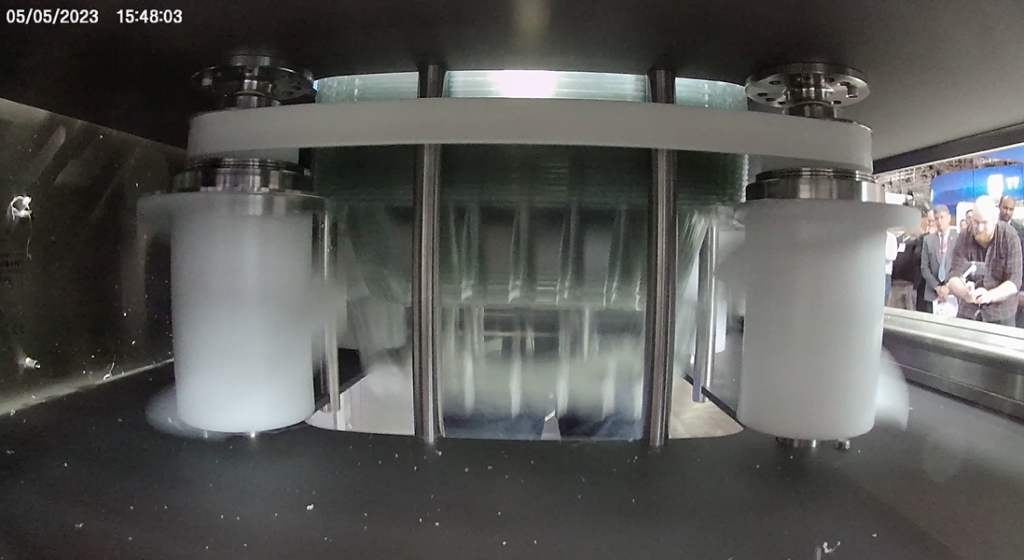

Slow motion footage of the record attempt. Notice how close the trays are to each other when released from the tool. 18.23 trays per second!

We had many ideas on how to solve this. One of the things we discussed was using air to transport the trays away from the tool. In theory it could be possible to control and forward the denested trays to the next point in the operation, with pneumatic tubing instead of traditional conveyors, however it would not be very flexible nor cost-effective.

Instead, we solved it in the tray denesting tool also. The screws accelerate the trays down the spindle, so the trays are released faster than the gravitational pull.

They still slow down mid-air, but late enough to be removed manually. That is why we had an operator on the floor to push the trays away. We also added a plate on the machine frame that would also bounce the trays away.

The 3rd Attempt

When the INTRAY Smart Stand Servo was assembled and we fired it up for the first time, it ran perfectly! Very few glitches and technical issues showed during the build. And would you believe it: we have never had a tray error with this machine! In fact, it can even run with used trays… it’s just THAT reliable!

And yes, it can run faster. It is not the mechanics that are holding the speed back, but the sensors. If it should run faster, it would need other sensors able to run more hertz.

A look inside the Smart Tool while running. With 18.23 trays per second it almost matches a normal video camera framerate, but otherwise too quick to see with the naked eye.

Our 3rd attempt at interpack 23 would have been well above 1,100 trays, but the sensor had a glitch during the attempt, so hundreds of trays wasn’t counted. In our workshop our sensors were connected to the screen over WiFi, but at interpack we had to cable it shortly before the record, as there was so much disturbance in the radio waves creating latency. We suspect the sensor may have jumped back to WiFi before the 3rd attempt.

Nevertheless, the trays were denested without any tray errors.

The Trays

The trays we used were ultra low stacking types of trays with only 1mm gap between them. We just love these trays as they are among the most sustainable choices of trays available today. They are very predictable and have a strong edge and bevel that can withstand high capacity denesting. We found them to be the best choice for this world record attempt.

That said, it is possible to reach very high speeds with other types of trays also with this machine. But many factors play in: Tray size, tray weight, stack height, resilience and tray shape. Pushing the limits of the machine is also pushing the limits of the trays, no doubt.

Why We Did It…

Leaders in denesting innovation. This was written above our exhibition at interpack 23. And we insist on staying innovative and push the boundaries of what is possible. We do this every day for our partners and customers.

It is vital to keep pushing the limits when building a sustainable future and reliable food production capable of supporting a growing world population.

The learnings we got from building for this world record will go directly into both existing and future products. Just like Formula 1 is an innovative space for road car technology.

Even if no line is able to handle 1,094 trays per minute, we hope to have inspired the technology manufacturers to keep pushing and work towards the perfect automation scenario. If every factor is optimized, we could collectively reach much higher automation output than we already do.

We would love to work together on a case with Tray Sealing companies on building the optimal case for this. We can absolutely deliver the speed and reliability needed!

Quality. Quantified.

Thank You

We want to thank these companies in particular:

Sealpac UK & Partners

Sealpac GmbH

Schneider Electric

JMC Packaging Ltd.

Faerch Group

Handtmann Ltd

Danish Export Association

Finnvacum Oy Ab

Steen FoodTec

Klöckner Pentaplast

Marel

MULTIVAC Group

Zultech Solutions

Packaging Journal

Packaging Europe

Plus Pack

JEROS A/S

Sofina Foods Inc.

Hilton Foods UK

Empirical Packaging Solutions

Cabinplant

VARIOVAC PS SystemPack GmbH

Farm Foods Australia

Lerøy Seafood Group ASA

ITW Dynatec

MULTIPOND Group

Nordvac GmbH

Havel-Maschinen.at

Ultrapak – packaging machines

Weber Inc.

Ishida Europe Ltd.

Macs Food Handling Solutions

Proseal UK Ltd.

Sismatec B.V.

Janssen Technical Solutions B.V.

Beijing Nantsune Meat Machinery Co., Ltd.

NASCO Corporation

Schweid & Sons

Cargill

Creminelli Fine Meats LLC

Footprint

Dennis Group

WEB Engineering

Little Leaf Farms

ILPRA

Promach Inc.

Unifiller Systems

Package Devices LLC

Interpack

Food & Drink Technology