The World May Be Changing Faster Than Your Production Line

To keep a business and production-line rolling we must think in different ways to meet the various demands coming.

The World May Be Changing Faster Than Your Production Line

New demands keep arising in the Food Production Industry. With more people on the planet our environmental footprint is rapidly becoming an issue. Producing food for – soon – 8b people in various cultures have logistic challenges and local rulesets. To keep a business and production-line rolling we must think in different ways to meet the various demands coming.

The keyword here is ‘Flexibility’. Flexible production has been a topic for many years, but what does it actually mean from a Food Production perspective?

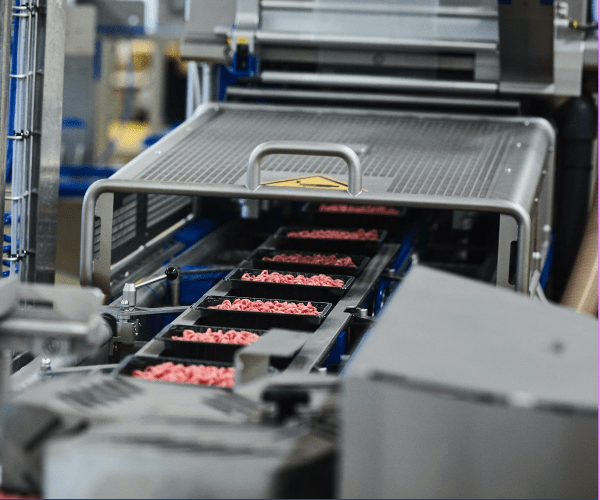

Picture yourself as a Poultry Factory. You can process thousands daily that all ends up in plastic-trays and palleted ready to ship for the stores. That plastic-tray is always in question these days, but we know it is plastic for a reason – the longevity of food is longer which should lead to less food-waste. Food-waste have a much higher impact on the environmental footprint than the plastic tray.

Nevertheless, new materials are still getting researched. In 2019 Danish Crown, one of Denmarks biggest Food export companies, changed their production line and started using trays made of PET-plastic instead. That’s more than 55 million meat trays! That’s not an easy change to impose on the production line. The traydenesters had to get an overhaul to meet this new demand.

The demand could also come from the markets selling the wares. The size of the tray and how much space it may fill in the freezer. The same product may end up being packaged in many different trays for various markets. You may not recognize this currently, as that consideration could take place at a whole different place in the value-chain.

Flexibility. Keeping the production-line agile enough to cope with new demands is key when designing production today. The entire line, from processing over packaging to End-of-Line operations. If the line is only able to do one or two things, you may face trouble down the road. Even if you don’t have a clear picture of what lies ahead, you should ensure that flexibility in your investments is included. Can you handle different cuts? Can you handle different tray-sizes of various materials? And can you pallet these without much downtime and further investment for bolt-on solutions? And are these solutions then flexible per se?

Flexibility is the answer to a lot of Risk Assessment today. Making the right investment and choice of technology that can easily be adapted or changed can save a lot of headaches down the road. And be a lot less expensive as a whole.

QUPAQ delivers flexible denesting and loading solutions. Tools can easily be changed in minutes to keep the downtime at a minimum when changing for different tray-types. This expands through the whole End-of-Line. If you can process it QUPAQs range of products can quickly adapt and keep the wheel turning, so to speak.

But flexibility should happen at all places. It’s a mindset where a company can quickly support new demands and market changes and protect itself from disruption.