A Closer Look: Unraveling Tray Packaging Operations in Food Manufacturing

A closer look on everything that goes on when packaging food in trays.

PART 1:

From Processing to Tray Sealing.

It may seem straightforward: processing food, packaging it, and shipping it to retailers. But there is of course more to it than that. Automated tray packaging lines have several subtasks embedded to ensure high efficiency, flexibility, and operational uptime. Here, we will dive deeper into the inner workings of packaging operations.

Assume that the food – whatever the product is – has been processed and is outputted on a conveyor line. These lines can, of course, have different configurations depending on the product.

1. Product Buffer

A buffer is used in manufacturing to adjust for variations in the production process affecting capacity. Think of a buffer as a safeguard to ensure your production line continues to run smoothly despite unforeseen factors coming into play. A product buffer ensures that products are delivered evenly at a certain pace in sync with the other machines in a packing line. It also ensures that IF anything should happen on the processing side, the packaging machines will continue with the products stored in the buffer. Product buffers are a relatively new concept within food manufacturing and are not part of all production lines.

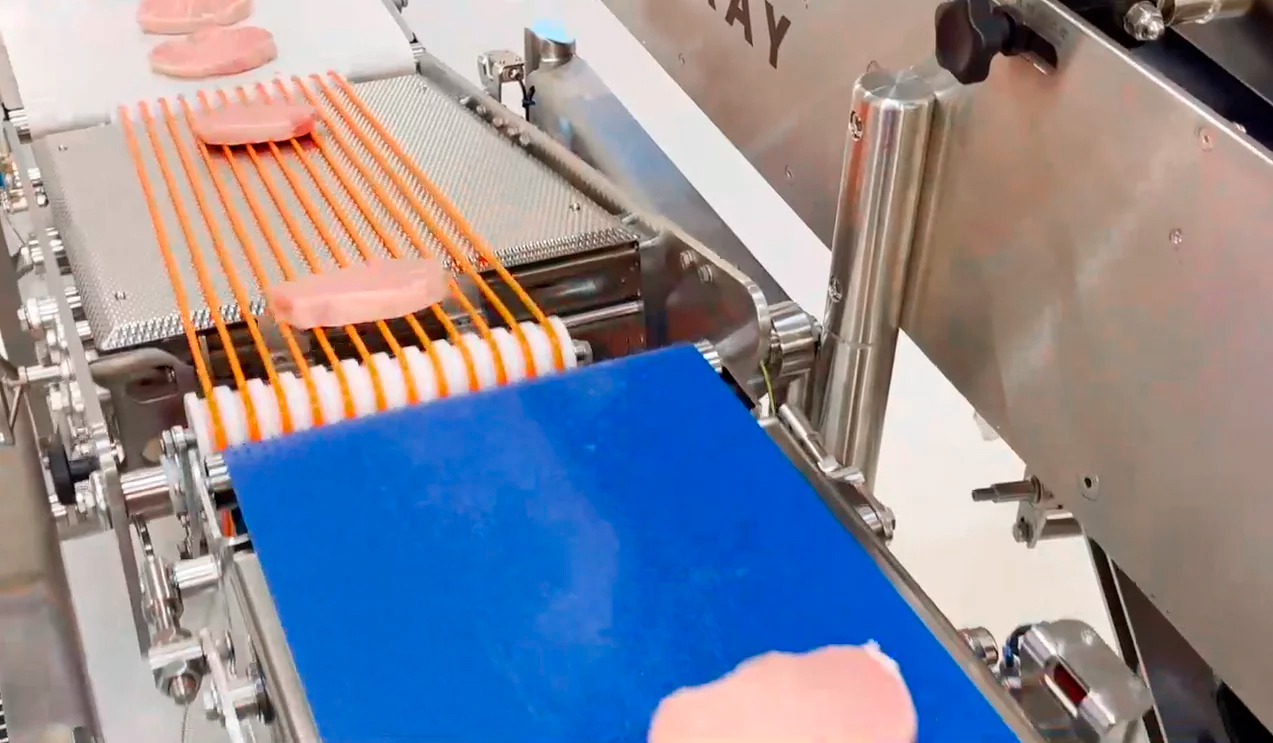

The INTRAY SideFlex distribute – in this case – pork chops from left to right on a conveyor. This makes it easier for a Product Loader later to place the products gently into trays and make the end product visibly pleasing.

2. Product Alignment

When the product continues, it must be aligned properly for packaging. Usually, this means rotating and/or positioning the product on the line, so all products have the same orientation when they enter the tray. The more precise this is, the fewer mistakes will occur later on, ensuring a high(er) uptime overall in the packing area. It also presents the product in the tray in a uniform way and lowers the complexity greatly on the Product Loader. The INTRAY SideFlex is an example of a machine for Product Alignment.

Read also: Avoid downtime: Log and monitor tray denesting success rate

3. Tray Denesting

Next, you will find a tray denester. This separates nested trays from each other and outputs them on a separate line. Tray denesters come in many configurations depending on product type, capacity requirements, and of course, the type of tray you wish to use. Tray denesters can also have a buffer embedded, ensuring that the denesters can run for hours on end before they need to get more trays loaded. If the Food Manufacturer uses more than one type of tray, the denester should be able to adapt quickly on the same line. The INTRAY Smart Servo series tray denesters have the added benefit of an auto-correct feature if a tray error should occur.

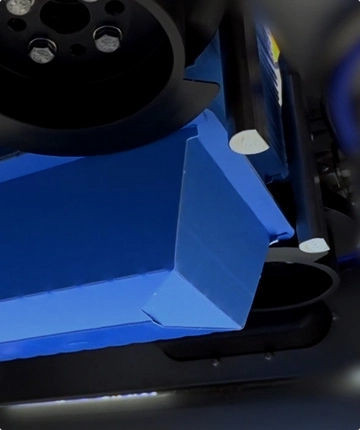

Inside an ANYTRAY series denester. Trays comes in many different sizes and materials. It can be a delicate matter to separate them reliably. With a buffer attached to the denester it can run for hours unmonitored.

4. Product Loading

A product loader joins the product line and the tray line, and ensures that products get loaded gently into trays with precision. Food Manufacturers with few product variations often combine the tray denester and product loader into the same machine, such as the INTRAY Steploader. This is a cost-efficient solution that takes up very little space compared to the alternative. But Product loaders can also be stand-alone solutions such as the INTRAY Easy Loader series or the ANYTRAY Portion-2-Pack series. Some companies still have manual product loading, why QUPAQ also produces manual packing lines.

5. Tray Buffer

From the product loader, the line continues with filled trays. The trays should now be buffered for the tray sealer down the line. As with a product buffer, a tray buffer ensures a higher output during possible downtime at other points on the line. A lot of manufacturers still don’t use tray buffers before their tray sealers, but we highly recommend doing this, as a tray sealer can be one of the slowest machines on the line, and you want it running as much as possible. Therefore, the ROI gain can be significant by implenting a tray buffer into your line.

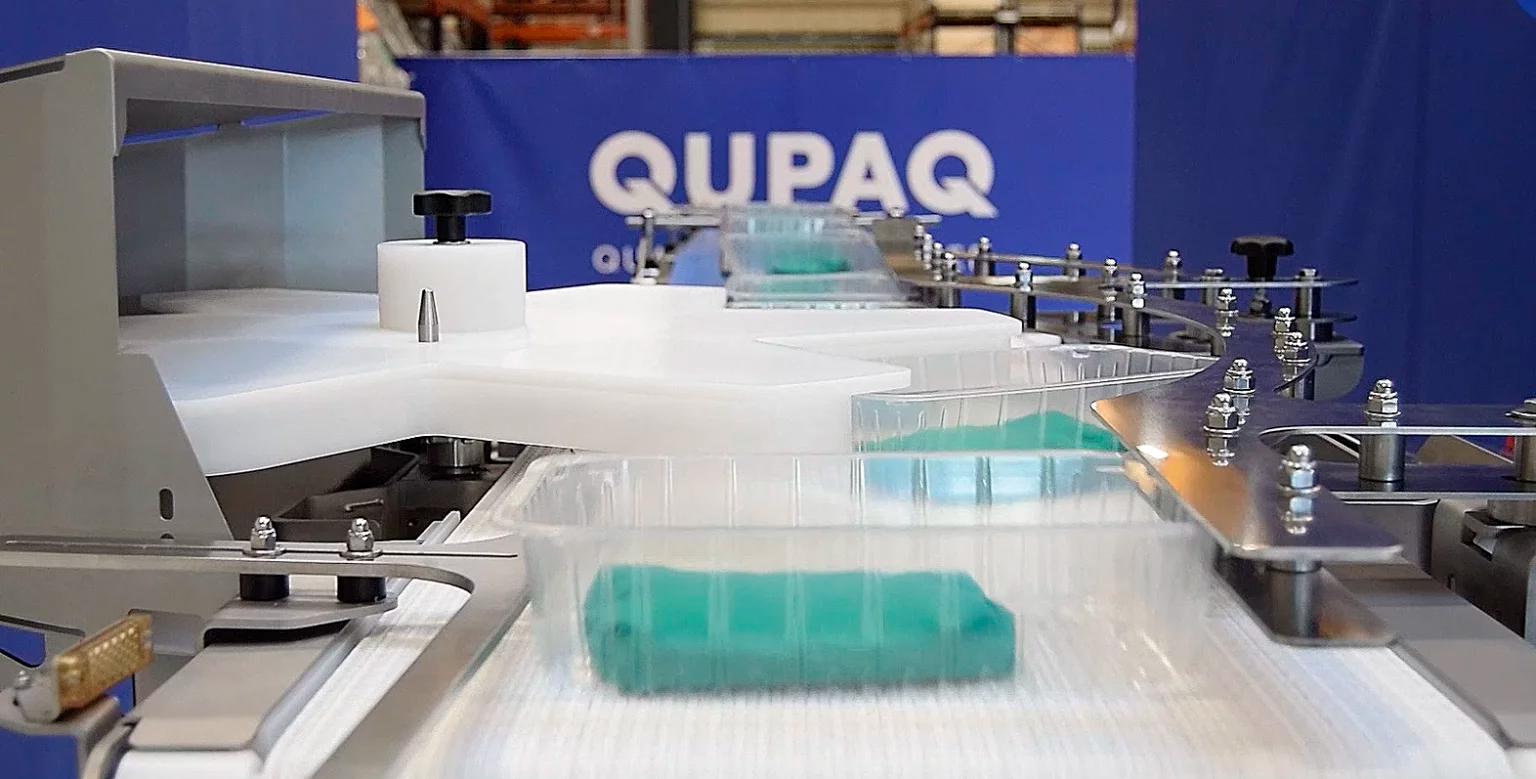

The QUPAQ Starwheel turns trays from long side leading to short side leading – or vice versa. It also acts as a buffer on the line.

6. Tray Alignment

Before entering the tray sealer, trays must be aligned properly. In some cases, it is possible to diverge the trays, splitting the line from a single lane to a twin lane, optimizing the output significantly. For this purpose, QUPAQ makes the Starwheel, LeanOne Diverger and INTRAY Tray Turner.

7. Tray Sealing

Trays enter the tray sealer. QUPAQ does not make tray sealing solutions as there are already many good solutions for this from various vendors all around the world. Instead, we partner with the best and we are able to deliver a full operational line with high compatibility with our product range.

Overall, we recommend using as few different tech vendors as possible on a food production line. The more providers used, the more dialogue is needed, and ensuring that all of them comply with the many regulations that are in play is almost a project on its own. Even if there are many different subtasks and technologies mentioned here, most of them are not rocket science. Here, we suggest that you focus on the tray denester, product loader, and tray sealer, and then get the rest from the vendors of those. Hence, you ensure that compatibility is proven and a good sync lowering the complexity greatly resulting in project success.

In the next part we will zoom in on what happens on a production line after the Tray sealer.

Read also: Unleashing Cost Savings: The Power of Automation in Food Manufacturing