What’s the Beef With Beef?

US Meat Export has become a thriving business. The Meat export numbers from 2022H1 showed significant increase – especially with beef.

US Meat Import and Export 2022

There may be a lot of chatter these days about meat production: How sustainable it is, how it can be substituted and how the many added increased costs for both livestock and manufacturing can be overcome. But at the end of the day the demand is not declining.

American Meat Production has become a thriving export business. The Meat export numbers from 2022H1 showed significant increase – especially with beef. Up 6% from the previous year.

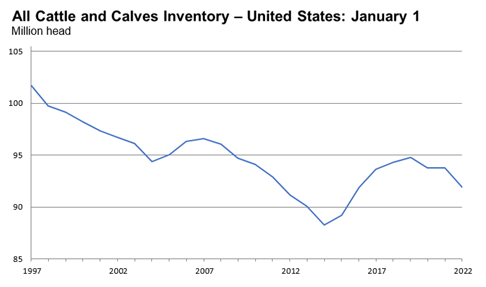

The number of cattle in the US is declining, however. In January 22 there were 91.9m head of cattle, out of which 20.1m were beef cows. That’s down 2% from previous year. And the summer drought 2022 may have decreased this number even further come January 2023.

The American export primarily goes to Asia – Japan, South Korea and China – and secondary to the neighboring countries of Canada and Mexico.

So where does all that meat come from?

The Brazilian Connection

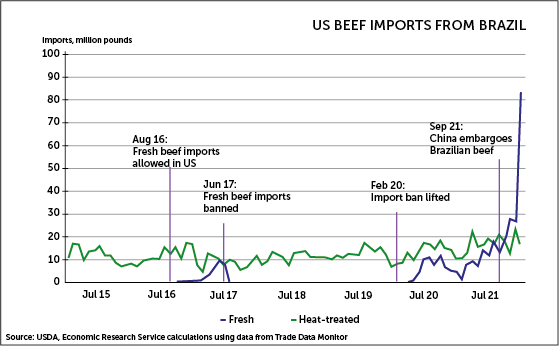

In 2020 the import ban on fresh meat from Brazil was lifted and the import skyrocketed in January 22 but have slowed its pace a little. New Zealand and Australia both have had an uplift in their export of Meat to US in 2022. The main import of beef is still from Canada and Mexico.

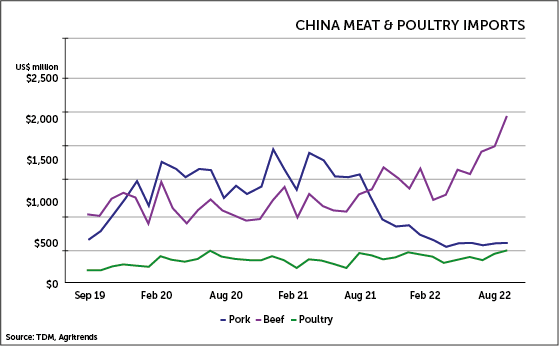

Overall, there haven’t been a huge increase in US meat import despite the huge uplift in export since 2017. Yet. But as the global meat consumption level continues to rise – especially in China – it could be a necessity to import more meat in the future – at least as long as the price for meat remains high. China imported 274,000 tonnes of beef in July 22, valued at a record $US1.8 billion.

Also read: When inflation increase, meat consumption increases…!

In september 2021 China embargoed meat from Brazil. The abundant meat was in large numbers bought by US who instead began a huge export towards China.

Chinas share of the market have been a hockey stick graph since 2014, growing even steeper since US took part in the market in 2017. But that’s just raw meat export. It is still mainly Chinese companies who process it.

So What’s the Beef?

For the US Meat Processors this could prove to be a challenge, when outside demand has risen so much and pushes the price of meat upwards. More so than just the general inflation. US produced meat goes to China, and Brazilian meat goes to US. This is a difficult supply chain to sustain.

Read also: Cost per unit – Food Manufacturings main KPI during inflation

The market fluctuations and costs on meat have shown high volatility. But when China lifts the embargo on meat from Brazil, hopefully prices will begin to settle. In the meantime, it makes sense for Meat Processors to optimize the costs within their control. Getting the packaging operations automated, identifying the best and most cost-efficient trays for the product and increase capacity wherever possible. Or build facilities closer to the demand – this is seen in Europe with Danish Crown announcing a new factory in the UK to produce 300 metric tons of bacon every week.

QUPAQ are the leader in tray denesting innovation and have a long-proven track-record of success with thousands of installations all around the world. If you want to ramp up and increase your growth on new markets or be better prepared to withstand the impact of external cost levels – either by adding flexibility (High Mix, Low Volume) or increasing capacity – QUPAQ are always ready for a talk.

We could begin by evaluating the trays you use and give you a test result on how much you will gain?