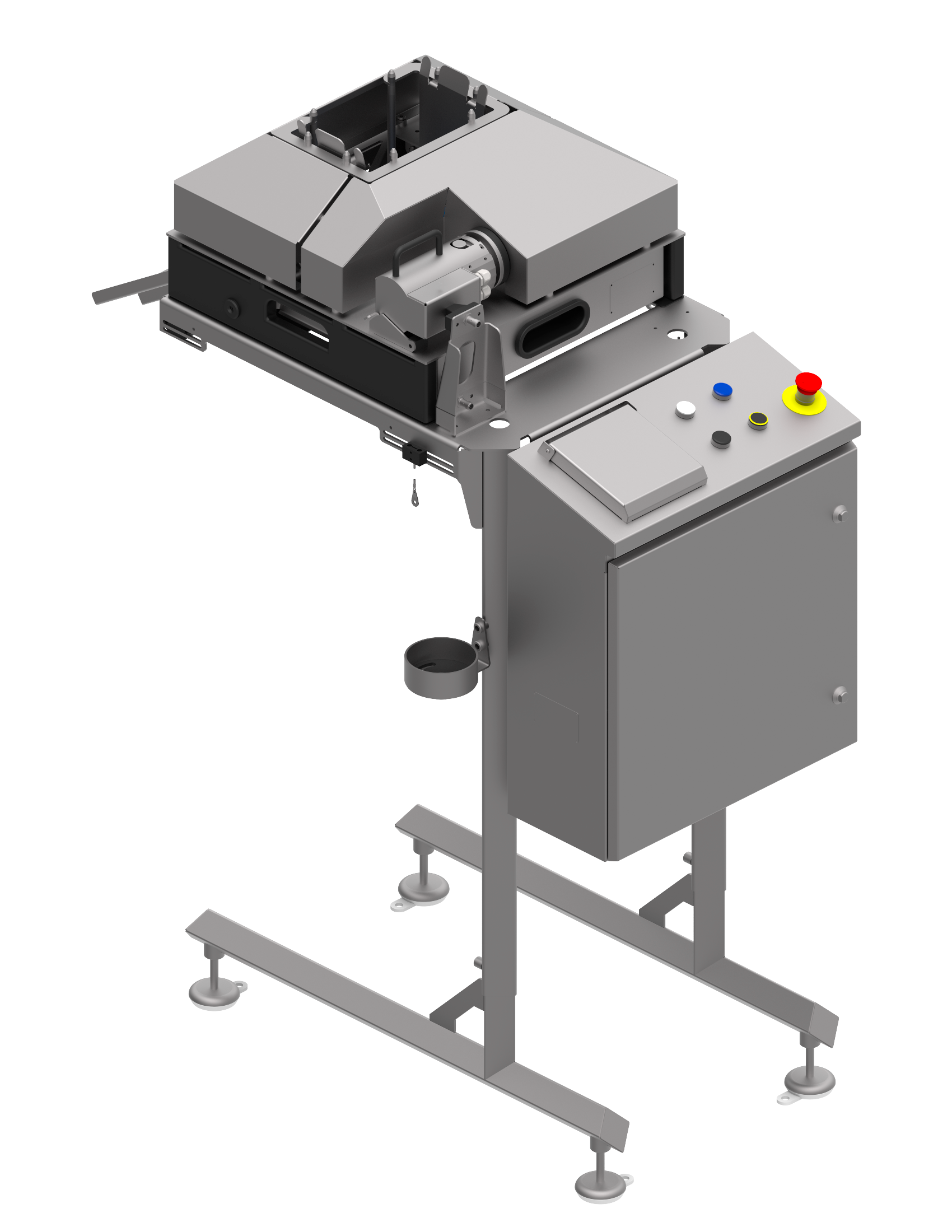

ANYTRAY Cleanline Tool – Flatskin

Empower your denesting process with a reliable electrical solution offering swift, precise handling of flatskin cardboard.

Need paperboard denesting?

Fast and Reliable Paperboard Denesting

The ANYTRAY Cleanline Tool – Flatskin is your solution for denesting various types of flatskin cardboard. This electrical tool ensures swift and reliable denesting, optimizing your workflow with accurate processing of up to 90 paperboards per minute.

Harness the Benefits and Integrate with the Flatskin Rack

Customized for specific paperboards, the ANYTRAY Cleanline Tool – Flatskin, in conjunction with the ANYTRAY Cleanline Rack – Flatskin, allows for a seamless 1-minute tool change. This feature facilitates handling multiple cardboards of different sizes and materials, ensuring uninterrupted production flow.

It is a cost-effective, low-maintenance, and hygienic design. It is safe, simple, and scalable.

Technical Specifications

Weight of machine

Approx. 42 kg

Tray length – max length

310 mm

Tray width – max width

250 mm

Infeed height

1000 mm +/- 350 mm

Outfeed height

1000 mm +/- 350 mm

Power supply

1×100-240 VAC+N+PE

Power consumption

0.5 A

Max fuse

10 A

Frequency

50-60 Hz

Max short circuit current (Ik max)

6 kA

Voltage for valves

24 V DC

Operational temperature

32°F-95°F/0°C-60°C

Stock temperature

14°F-140°F/-10°C-60°C

Humidity

10%-90%

Noise level

< 80 dB (A)

Steel quality

EN 1.4301, AISI 304

Three Reasons to Choose the

ANYTRAY Cleanline Tool – Flatskin

EFFICIENT CLEANING

A clean production is key. The hygienic design makes cleaning and maintenance of both the tool and additional ANYTRAY equipment easy and efficient.

EASY CHANGE-OVER

The solution is designed to ensure a quick switch between tray sizes, and still keep your production speed at the highest level. You just need to switch the tool.

UP TO 90 TRAYS PER MINUTE

Maximize your production capacity with high-speed, automated paperboard denesting of up to 90 trays per minute. The most reliable solution on the market.