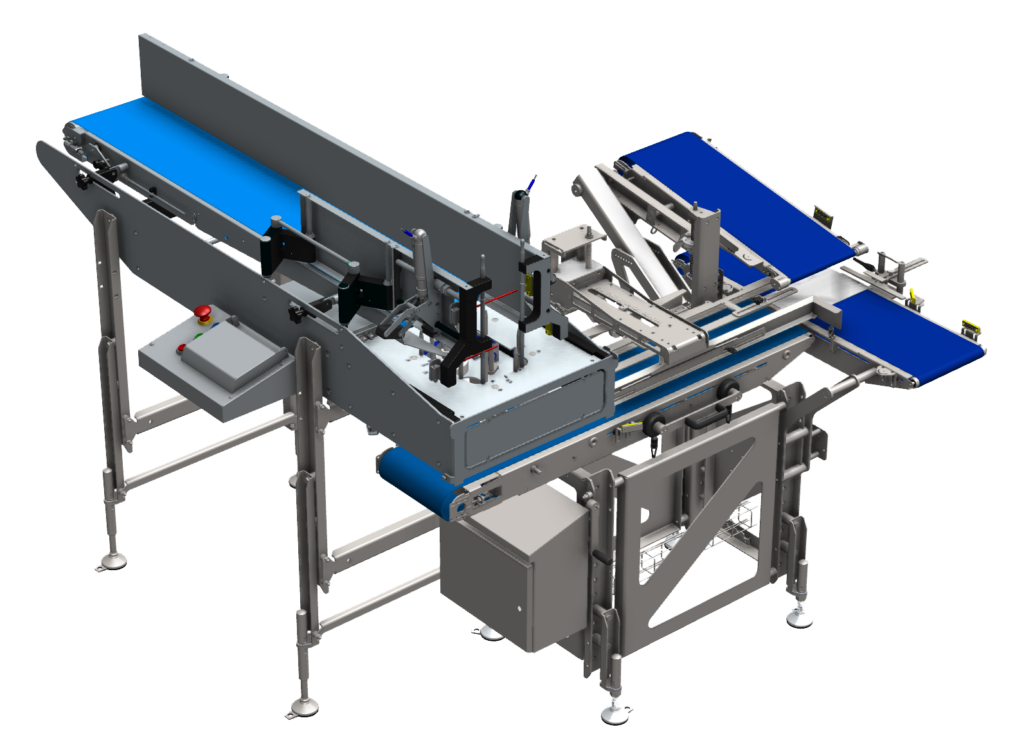

QUPAQ Easy Loader

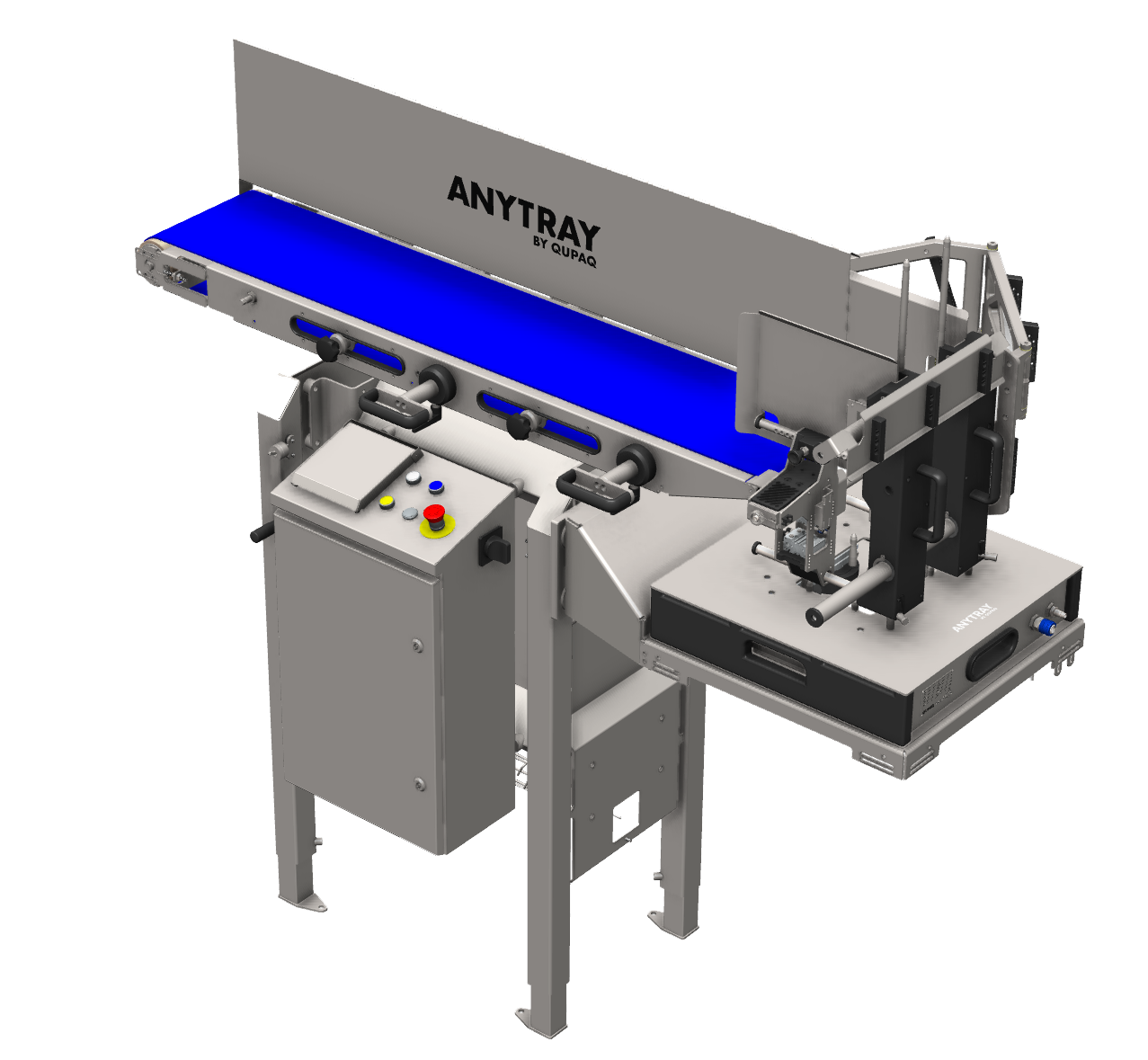

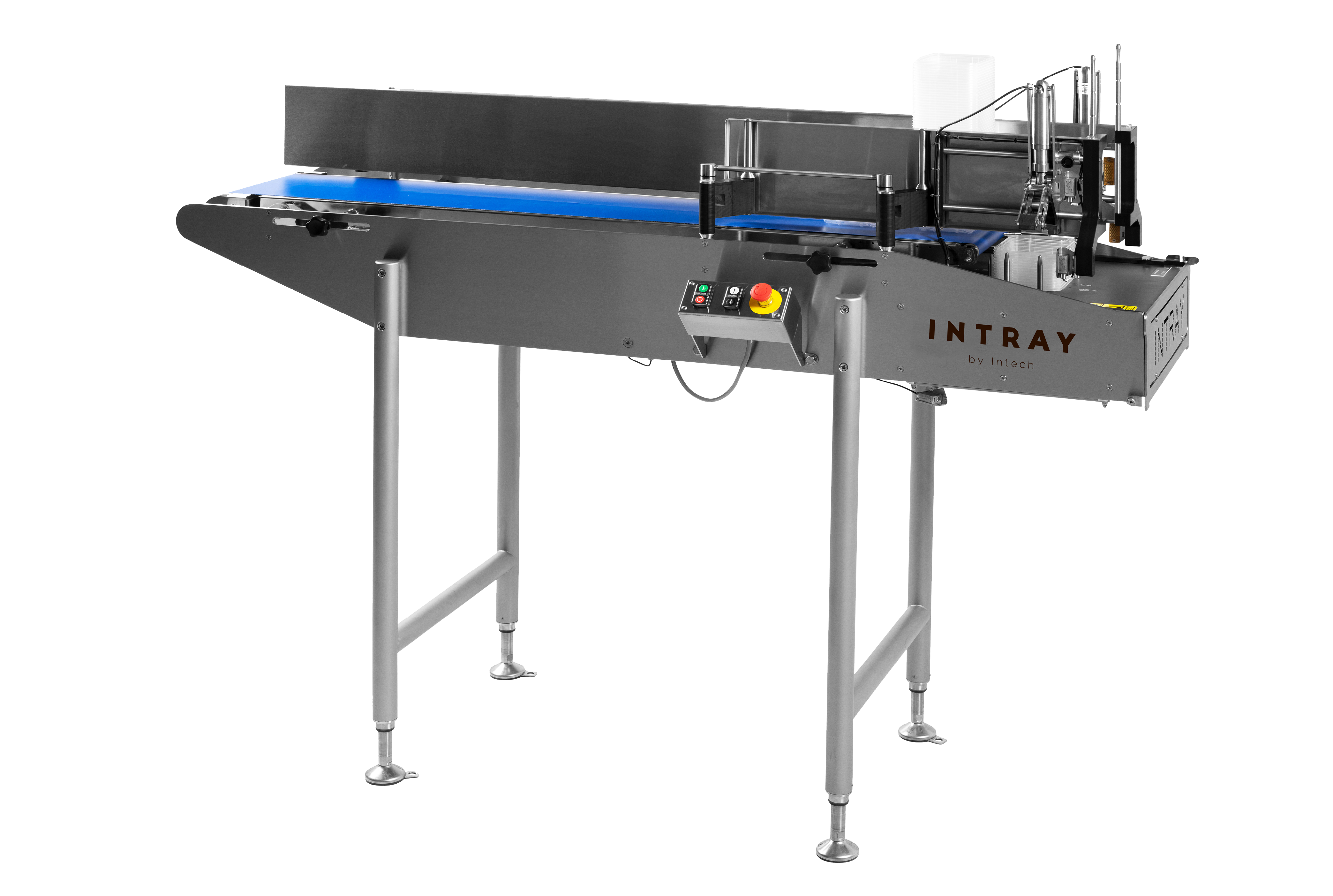

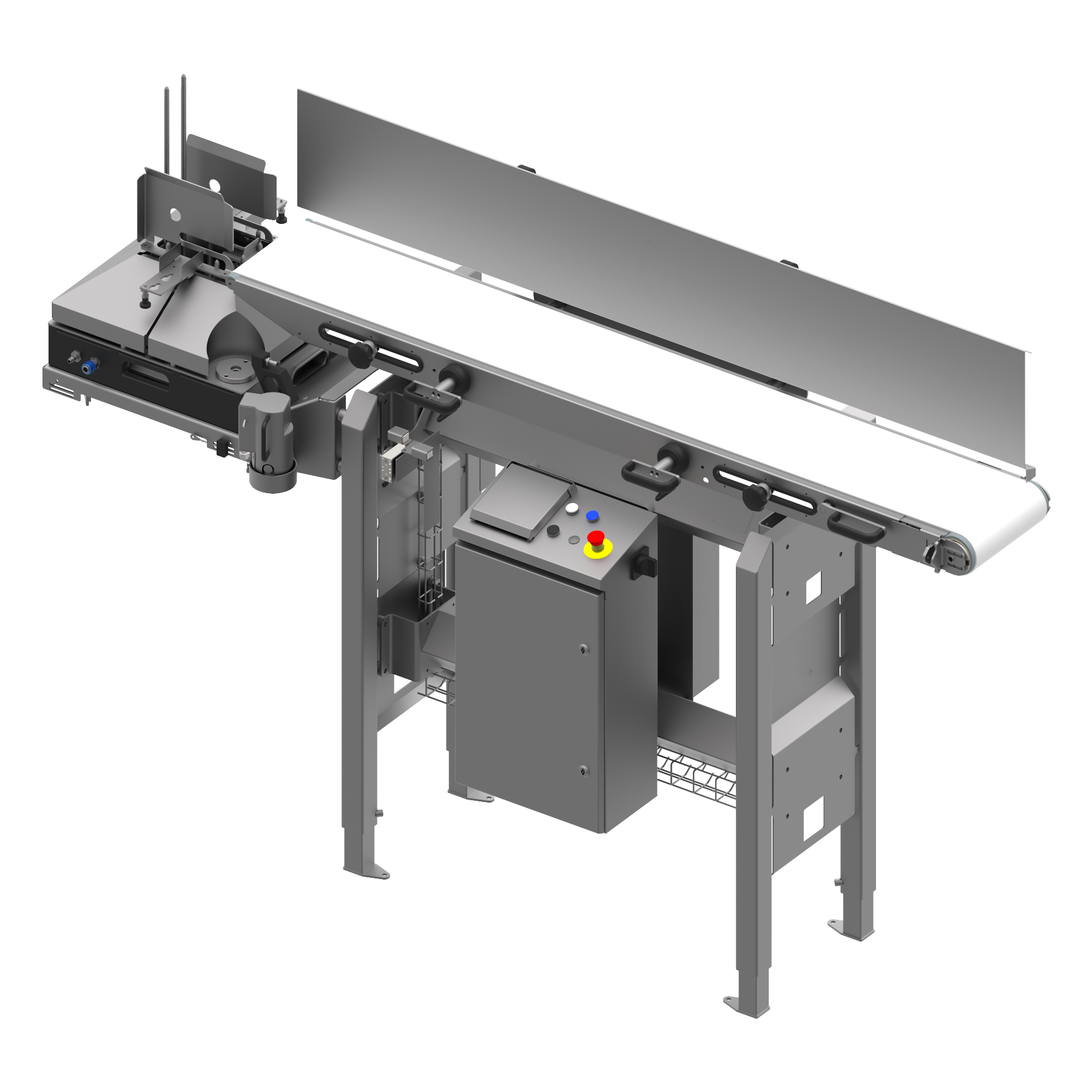

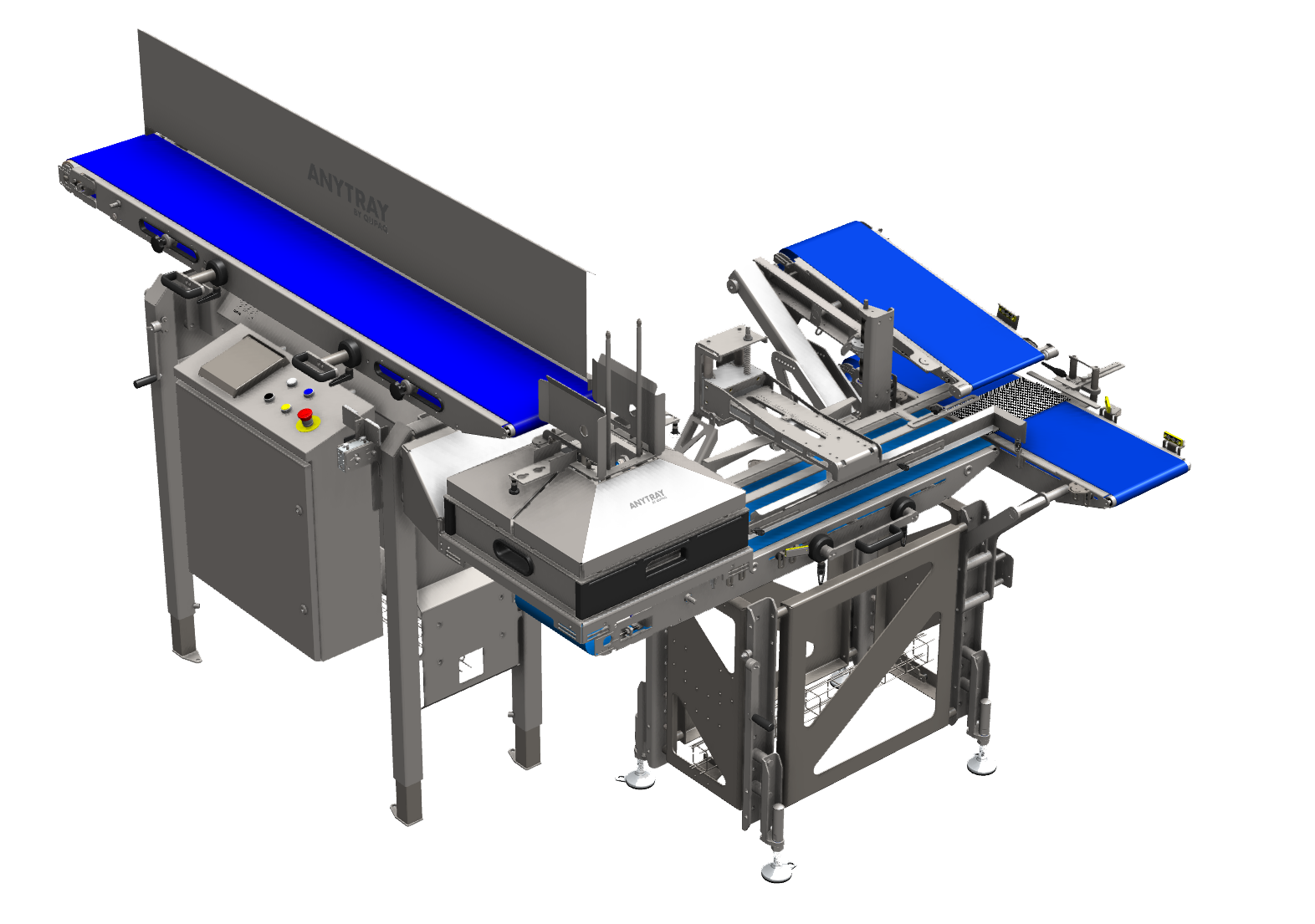

Designed for high-volume productions featuring minced products, the QUPAQ Easy Loader is a scalable solution tailored to meet your production demands effectively.

Fast loading of minced products

Automatic Tray Loading

The QUPAQ Easy Loader functions as an automatic tray-filling system, that transport products from processing, filling portions into trays, and subsequently forwards the loaded tray to your tray sealer at a speed of up to 90 trays per minute.

Designed for high-volume productions featuring minced products, the QUPAQ Easy Loader is a scalable solution tailored to meet your production demands effectively. Adapt to running multiple products on the same line with our options. Whether loading two different products (e.g., burger patties) into the same tray or forwarding an empty tray for manual loading, our adaptable options provide the flexibility you need.

Flexible Tray Feeding

The QUPAQ Easy Loader is compatible with both Rack and Buffer solutions, and it supports various denesting options, including Cleanline, LeanOne, and Smart form factors. This ensures flexible easy one-minute changeovers for diverse tray types.

Handcrafted in Denmark using stainless steel, the QUPAQ Easy Loader features a cost-effective, low-maintenance, and hygienic design, ensuring reliability and efficiency in your production environment. The compact design facilitates fast and easy integration into any existing production line.

Three Reasons to Choose the

QUPAQ Easy Loader

VERSATILE COMPATIBILITY

The QUPAQ Easy Loader support various denesting options and tray types, offering adaptability to meet your diverse production needs.

EFFICIENCY AT SCALE

Designed for high-volume minced product productions, the QUPAQ Easy Loader operates and ensures efficiency at a speed of up to 90 trays per minute.

EASY AUTOMATION

The QUPAQ Easy Loader offers a compact, hygienic, and easy-to-maintain design, ensuring easy integration into any existing line for efficient automated tray filling.

Technical Specifications

Weight of machine

Approx. 55 kg

Tray length – max length

360 mm

Tray width – max width

280 mm

Infeed height

1000 mm +/- 350 mm

Outfeed height

1000 mm +/- 350 mm

Power supply

1×100-240 VAC+N+PE

Power consumption

0.5 A

Max fuse

10 A

Frequency

50-60 Hz

Max short circuit current (Ik max)

6 kA

Voltage for valves

24 V DC

Air consumption

300 L (120 tray/minute)

Air pressure

6 Bar

Operational temperature

32°F-95°F/0°C-60°C

Stock temperature

14°F-140°F/-10°C-60°C

Humidity

10%-90%

Noise level

< 80 dB (A)

Steel quality

EN 1.4301, AISI 304